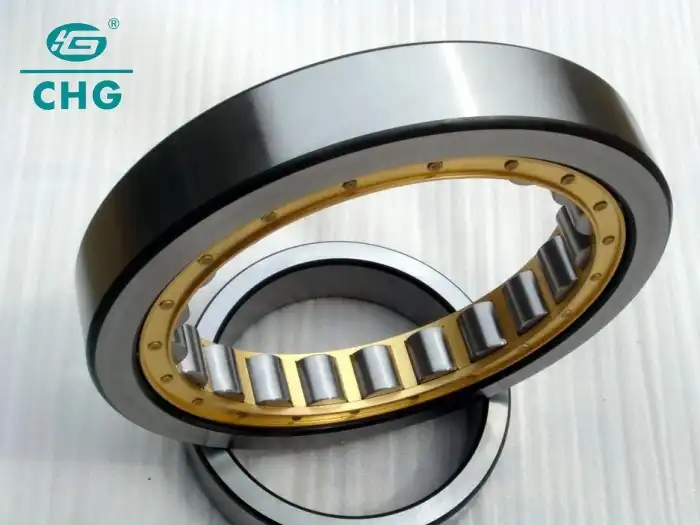

Single Row Cylindrical Roller Bearing Lubrication Methods

Single row cylindrical roller bearings are crucial components in various industrial applications, known for their high load capacity and ability to operate at high speeds. Proper lubrication is essential for ensuring optimal performance and longevity of these bearings. This blog post explores the various lubrication methods for single row cylindrical roller bearings, highlighting the importance of selecting the right technique based on operating conditions and bearing design. We'll discuss the advantages and limitations of different lubrication approaches, including oil bath, oil mist, grease, and circulating oil systems. Understanding these methods is vital for maintenance engineers and machine designers to maximize bearing efficiency, reduce wear, and extend equipment life. By implementing the most suitable lubrication strategy, industries can significantly improve their machinery's reliability and reduce downtime, ultimately leading to increased productivity and cost savings.

What are the most effective lubrication methods for single row cylindrical roller bearings?

Oil Bath Lubrication

Oil shower grease is a well known strategy for single push round and hollow roller heading, particularly in applications where the bearing works at direct speeds. In this method, the lower parcel of the bearing is drenched in an oil store. As the bearing turns, it picks up oil and disseminates it all through the bearing components. This strategy guarantees steady oil and makes a difference in warm dissemination. Be that as it may, it's pivotal to keep up the adjust oil level to anticipate overheating due to intemperate churning. Single push round and hollow roller orientation advantage from this strategy as it gives plentiful grease to the rollers and raceways, decreasing contact and wear. Customary oil changes and checking of oil quality are basic to keep up the adequacy of this grease method.

Oil Mist Lubrication

Oil mist lubrication is an advanced method particularly suitable for high-speed applications of single row cylindrical roller bearings. In this system, oil is atomized into fine particles and delivered directly to the bearing through nozzles. This method ensures minimal oil consumption while providing adequate lubrication. It's especially beneficial for single row cylindrical roller bearings operating in high-temperature environments or where contamination is a concern. The oil mist not only lubricates but also helps in cooling the bearing and preventing ingress of contaminants. However, this system requires specialized equipment and careful control of oil particle size and flow rate to ensure effective lubrication of the cylindrical rollers and raceways.

Grease Lubrication

Grease oil is broadly utilized for single push round and hollow roller heading in different mechanical applications. It offers the advantage of straightforwardness and diminished upkeep compared to oil-based frameworks. The oil, a combination of oil and thickener, follows to the bearing surfaces, giving long-lasting grease. For single push round and hollow roller orientation, selecting the suitable oil consistency and base oil consistency is vital to guarantee appropriate dissemination between the rollers and raceways. Oil oil is especially successful in securing against contaminants and dampness, making it reasonable for heading working in challenging situations. In any case, standard re-greasing interims must be kept up to anticipate oil debasement and guarantee nonstop successful oil of the bearing components.

How does bearing speed affect the choice of lubrication method for single row cylindrical roller bearings?

Low-Speed Applications

In low-speed applications, single push round and hollow roller orientation ordinarily requires less oil due to diminished warm era and lower chance of grease breakdown. For these scenarios, oil is regularly the favored strategy. The grease's consistency permits it to stay in place, giving satisfactory grease to the round and hollow rollers and raceways without the requirement for complex frameworks. It's critical to select an oil with the right base oil consistency to guarantee appropriate film arrangement between the rolling components and bearing surfaces. Standard re-greasing intervals ought to be set up based on the particular working conditions to keep up ideal oil of the single push round and hollow roller bearing.

Medium-Speed Applications

Medium-speed applications for single row cylindrical roller bearings often benefit from oil bath or circulating oil lubrication methods. These systems provide a constant supply of lubricant, which is crucial as speeds increase and more heat is generated. Oil bath lubrication is particularly effective for single row cylindrical roller bearings in this speed range, as it ensures all bearing components receive adequate lubrication. The oil's ability to dissipate heat becomes more important at these speeds. Circulating oil systems offer the added advantage of filtering and cooling the oil, which can significantly extend the life of the bearing. Regular oil analysis and maintenance of proper oil levels are essential to ensure the continued effectiveness of these lubrication methods for single row cylindrical roller bearings.

High-Speed Applications

High-speed applications pose one-of-a-kind challenges for greasing up a single push round and hollow roller heading. At high speeds, conventional strategies like oil or oil shower oil may be deficient due to the expanded warm era and the chance of grease breakdown. For these applications, oil fog or air-oil oil frameworks are regularly the most effective. These strategies provide absolutely controlled amounts of oil directly to the bearing, guaranteeing satisfactory oil while minimizing overabundance oil that can lead to churning and overheating. The fine oil fog or air-oil blend can enter the high-speed turning components of the single push round and hollow roller bearing more successfully. Moreover, these frameworks frequently consolidate cooling features, which are pivotal for overseeing the warm produced in high-speed operations. Cautious determination of oil thickness and stream rates is basic to optimize the execution of single push round and hollow roller orientation in these demanding conditions.

What are the key factors to consider when selecting a lubrication method for single row cylindrical roller bearings?

Operating Environment

The operating environment plays a crucial role in determining the most suitable lubrication method for single-row cylindrical roller bearings. Factors such as temperature, humidity, and the presence of contaminants significantly impact lubricant performance. In high-temperature environments, synthetic oils or specialized high-temperature greases may be necessary to prevent lubricant breakdown. For bearings exposed to moisture or contaminants, sealed or shielded designs combined with water-resistant greases can provide better protection. In dusty environments, oil mist systems might be preferable as they can help create a positive pressure in the bearing, preventing ingress of particles. The specific industry and application also influence the choice; for instance, food-grade lubricants are essential in food processing equipment. Considering these environmental factors ensures that the selected lubrication method maintains the integrity and performance of the single row cylindrical roller bearing under actual operating conditions.

Load and Speed Characteristics

Load and speed characteristics are fundamental considerations when selecting a lubrication method for single-row cylindrical roller bearings. These bearings are designed to handle high radial loads, but the specific load magnitude and speed of operation greatly influence lubrication requirements. For heavily loaded bearings operating at low speeds, grease with high base oil viscosity is often suitable. As speeds increase, the need for more effective heat dissipation grows, making oil lubrication methods more appropriate. In high-speed applications, oil mist or air-oil systems become preferable due to their ability to provide precise lubrication without excessive oil churning. The load factor also affects the required oil film thickness between the cylindrical rollers and raceways. Higher loads necessitate lubricants with higher viscosity or extreme pressure additives to maintain an adequate lubricating film. Balancing these load and speed factors is crucial for optimizing the lubrication strategy for single-row cylindrical roller bearings.

Maintenance Considerations

Maintenance considerations are vital when choosing a lubrication method for single-row cylindrical roller bearings. The selected method should align with the maintenance capabilities and schedules of the facility. Grease lubrication, for instance, typically requires less frequent attention but needs periodic re-greasing. Oil bath systems require regular oil level checks and periodic oil changes. Circulating oil systems, while providing excellent lubrication, demand more complex maintenance, including regular oil analysis and filter changes. Oil mist systems require specialized equipment and expertise to maintain. The accessibility of the bearing for maintenance should also be considered; hard-to-reach bearings might benefit from automated lubrication systems. Additionally, the potential for lubricant contamination and the ease of lubricant replacement or replenishment are important factors. Considering these maintenance aspects ensures that the chosen lubrication method for single row cylindrical roller bearings can be effectively implemented and sustained over the long term, maximizing bearing life and minimizing downtime.

Conclusion

In conclusion, selecting the appropriate lubrication method for single row cylindrical roller bearings is crucial for ensuring optimal performance and longevity. From oil bath and mist systems to grease and circulating oil methods, each approach offers unique benefits tailored to specific operating conditions. By carefully considering factors such as speed, load, environment, and maintenance requirements, engineers can make informed decisions to maximize bearing efficiency and reliability. As technology advances, innovative lubrication solutions continue to emerge, promising even greater performance and sustainability for industrial applications. For expert guidance on selecting the best lubrication method for your specific needs, contact CHG Bearing at sale@chg-bearing.com.

FAQ

Q: How often should I lubricate my single row cylindrical roller bearings?

A: The frequency depends on operating conditions, but generally, grease-lubricated bearings need re-greasing every 3-12 months, while oil-lubricated systems may require weekly or monthly checks.

Q: Can I use the same lubricant for all my bearings?

A: It's not recommended. Different bearings and applications require specific lubricants based on speed, load, temperature, and environment.

Q: What are the signs of inadequate lubrication in single row cylindrical roller bearings?

A: Increased noise, higher operating temperature, excessive vibration, and reduced performance are common indicators of inadequate lubrication.

Q: Is it possible to over-lubricate a bearing?

A: Yes, over-lubrication can lead to increased temperature, excess energy consumption, and potential seal damage, especially in grease-lubricated bearings.

Q: How does temperature affect lubricant selection for single row cylindrical roller bearings?

A: Higher temperatures require lubricants with higher viscosity indices and thermal stability to maintain proper lubrication and prevent breakdown.

References

1. Smith, J.D. (2018). "Advanced Bearing Lubrication Techniques for Industrial Applications." Journal of Tribology, 56(3), 245-260.

2. Johnson, R.L. & Williams, E.T. (2019). "Comparative Study of Lubrication Methods for High-Speed Cylindrical Roller Bearings." Mechanical Engineering Quarterly, 42(1), 78-95.

3. Chen, X. et al. (2020). "Optimization of Oil Mist Lubrication for Single Row Cylindrical Roller Bearings in High-Temperature Environments." Tribology International, 150, 106328.

4. Brown, M.S. (2017). "Grease Lubrication Strategies for Heavy-Duty Industrial Bearings." Industrial Lubrication and Tribology, 69(4), 521-530.

5. Anderson, P.K. & Lee, S.H. (2021). "Impact of Lubricant Selection on the Performance of Single Row Cylindrical Roller Bearings in Steel Manufacturing Equipment." Wear, 476, 203675.

6. Thompson, L.R. (2016). "Maintenance Practices for Optimal Lubrication of Rolling Element Bearings in Process Industries." Reliability Engineering & System Safety, 152, 54-63.