Manufacturing of Cylindrical Rollers: Grinding to Profiling

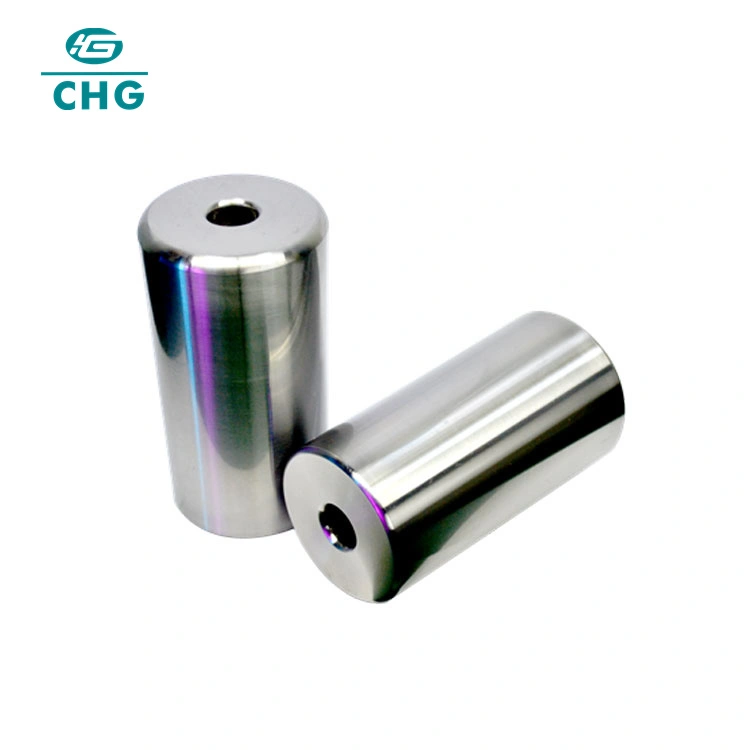

The manufacturing process of cylindrical rollers, from grinding to profiling, is a crucial aspect of producing high-quality bearings and other mechanical components. This intricate process involves several stages, each contributing to the final product's precision, durability, and performance. The journey begins with the careful selection of raw materials, typically high-grade steel, which undergoes a series of transformations. The initial grinding phase removes imperfections and achieves the desired dimensions, while subsequent profiling steps fine-tune the roller's shape to meet specific application requirements. Advanced technologies and rigorous quality control measures are employed throughout the manufacturing process to ensure that each cylindrical roller meets exacting standards. This blog will delve into the intricacies of cylindrical roller production, exploring the techniques, technologies, and considerations that go into creating these essential components for various industries.

What are the key steps in manufacturing cylindrical rollers?

Material Selection and Preparation

The fabricating of round and hollow rollers starts with the cautious determination of high-quality materials. Regularly, high-grade steel is chosen for its strength and load-bearing capacity. The steel experiences introductory preparing, counting cutting and warm treatment, to plan it for the consequent fabricating steps. This planning stage is pivotal as it sets the establishment for the roller's execution. The material's composition and beginning treatment altogether impact the last product's hardness, which for round and hollow rollers frequently ranges from 60 to 64 HRC. This hardness level guarantees that the rollers can withstand the tall stresses and loads they will experience in different applications, from wind turbines to mechanical machinery.

Grinding Process

The last arrange in the fabricating of round and hollow rollers includes profiling and wrapping up. This handle fine-tunes the roller's shape to meet particular application prerequisites. Profiling can incorporate making slight convexities or other geometrical highlights that improve the roller's execution beneath stack. Progressed machining strategies, such as CNC profiling, are utilized to accomplish the craved profile with tall exactness. The wrapping up prepare includes cleaning and surface treatment to diminish grinding and move forward wear resistance. Quality checks are performed at this arrange to confirm that the rollers meet the indicated review, which can extend from G1 to G2A. These grades show distinctive levels of exactness and execution capabilities. The last item experiences thorough review to guarantee compliance with worldwide benchmarks and certifications, such as ISO9001, ensuring that each round and hollow roller meets the most noteworthy quality benchmarks.

Profiling and Finishing

Cylindrical rollers play a vital part in improving the stack capacity and dispersion inside orientation. Their special plan permits for a bigger contact zone compared to ball heading, coming about in prevalent load-bearing capabilities. This characteristic makes round and hollow rollers perfect for applications that include overwhelming loads or stun loads. In wind turbines, for case, round and hollow roller orientation offer assistance disperse the enormous strengths created by the turbine edges over a bigger surface zone, diminishing stretch on person components. The capacity of round and hollow rollers to handle tall outspread loads whereas permitting for a few hub development makes them especially reasonable for applications where shaft diversion or misalignment may happen. This stack dissemination capability contributes essentially to the by and large solidness and unwavering quality of the bearing framework, amplifying the operational life of apparatus in different mechanical settings.

How do cylindrical rollers contribute to bearing performance?

Load Capacity and Distribution

Cylindrical rollers play a vital part in improving the stack capacity and dispersion inside orientation. Their special plan permits for a bigger contact zone compared to ball heading, coming about in prevalent load-bearing capabilities. This characteristic makes round and hollow rollers perfect for applications that include overwhelming loads or stun loads. In wind turbines, for case, round and hollow roller orientation offer assistance disperse the enormous strengths created by the turbine edges over a bigger surface zone, diminishing stretch on person components. The capacity of round and hollow rollers to handle tall outspread loads whereas permitting for a few hub development makes them especially reasonable for applications where shaft diversion or misalignment may happen. This stack dissemination capability contributes essentially to the by and large solidness and unwavering quality of the bearing framework, amplifying the operational life of apparatus in different mechanical settings.

Reduced Friction and Heat Generation

One of the key preferences of round and hollow rollers is their capacity to decrease grinding and warm era inside a bearing gathering. The rolling movement of round and hollow rollers, as contradicted to the sliding movement in a few other bearing sorts, minimizes contact between moving parts. This diminished grinding deciphers to lower vitality utilization and less warm era amid operation. In high-speed applications, such as in car transmissions or mechanical apparatus, this characteristic is especially useful as it makes a difference keep up ideal working temperatures and effectiveness. The exactness fabricating of round and hollow rollers, with their carefully planned profiles and surface wraps up, advance improves this low-friction execution. By minimizing contact and warm era, round and hollow roller heading contribute to made strides vitality effectiveness, decreased wear on components, and amplified benefit life of the apparatus they support.

Precision and Stability

Cylindrical rollers are famous for their capacity to give tall accuracy and solidness in bearing applications. The fabricating handle, which incorporates exact pounding and profiling, guarantees that each roller meets rigid dimensional and geometric resistances. This accuracy is basic in applications that require exact shaft situating and smooth turn. In aviation applications, for occurrence, round and hollow roller orientation in landing adapt frameworks give the solidness and exactness vital for secure flying machine operation. The steady measurements and surface quality of round and hollow rollers too contribute to decreased vibration and clamor in apparatus. This steadiness is especially profitable in high-precision fabricating gear, where indeed minor vibrations can influence item quality. By keeping up exact arrangement and minimizing runout, round and hollow rollers offer assistance guarantee the generally precision and unwavering quality of the frameworks in which they are utilized.

What are the future trends in cylindrical roller manufacturing?

Advanced Materials and Coatings

The future of cylindrical roller manufacturing is closely tied to advancements in materials science and coating technologies. Researchers and manufacturers are exploring new alloys and composite materials that offer improved strength-to-weight ratios, enhanced wear resistance, and better performance under extreme conditions. These advanced materials could potentially extend the lifespan of cylindrical rollers and expand their application range. Additionally, innovative coating technologies are being developed to further enhance the surface properties of cylindrical rollers. These coatings can provide increased hardness, improved lubrication retention, and better resistance to corrosion and contamination. For instance, ceramic coatings or diamond-like carbon (DLC) coatings are being investigated for their potential to significantly reduce friction and wear in high-stress applications. As these material and coating technologies evolve, cylindrical rollers will be able to perform more efficiently in increasingly demanding environments, opening up new possibilities in industries such as aerospace, renewable energy, and advanced manufacturing.

Smart Manufacturing and Industry 4.0

The integration of smart manufacturing principles and Industry 4.0 technologies is set to revolutionize the production of cylindrical rollers. Advanced sensors and data analytics are being incorporated into the manufacturing process to enable real-time monitoring and quality control. This allows for immediate detection of deviations and rapid adjustments to ensure consistent product quality. Machine learning algorithms are being developed to optimize the grinding and profiling processes, potentially leading to improved efficiency and reduced material waste. The use of digital twins in the design and testing phases could significantly reduce development time and costs for new cylindrical roller configurations. Furthermore, the implementation of additive manufacturing techniques, such as 3D printing of metal powders, may open up new possibilities for creating complex roller geometries or customized solutions for specific applications. These smart manufacturing approaches will not only enhance the quality and consistency of cylindrical rollers but also enable greater flexibility in production, allowing manufacturers to respond more quickly to changing market demands.

Sustainability and Environmental Considerations

As global focus on sustainability intensifies, the manufacturing of cylindrical rollers is adapting to meet environmental challenges. Future trends in this area include the development of more energy-efficient production processes, reduction of material waste, and the use of recycled or sustainable materials where possible. Manufacturers are exploring ways to optimize the use of resources throughout the production cycle, from raw material selection to final packaging. This may involve implementing closed-loop recycling systems for metal shavings and coolants used in the grinding process. Additionally, there is growing interest in developing biodegradable lubricants and environmentally friendly surface treatments that maintain the high performance standards required for cylindrical rollers. The push towards sustainability also extends to the design phase, with engineers working on roller configurations that require less material while maintaining or improving performance characteristics. These efforts in sustainable manufacturing not only reduce the environmental impact of cylindrical roller production but also often lead to cost savings and improved product efficiency, aligning environmental responsibility with economic benefits.

Conclusion

The manufacturing of cylindrical rollers, from grinding to profiling, is a complex process that demands precision, expertise, and advanced technology. As we've explored, these components play a crucial role in various industries, offering benefits such as high load capacity, reduced friction, and enhanced stability. The future of cylindrical roller manufacturing looks promising, with trends focusing on advanced materials, smart manufacturing, and sustainability. As the industry continues to evolve, companies like CHG Bearing are at the forefront, providing innovative solutions and high-quality products to meet diverse customer needs. For more information on our cylindrical roller offerings and how they can benefit your applications, please contact us at sale@chg-bearing.com.

FAQ

What is the typical size range for cylindrical rollers?

Cylindrical rollers typically range from φ20 to φ120mm in size, with custom sizes available based on specific requirements.

What level of accuracy can be achieved in cylindrical roller manufacturing?

High-precision cylindrical rollers can achieve national standard level 1 accuracy, with deviations controlled within ±0.001mm.

What are the main applications for cylindrical rollers?

Cylindrical rollers are commonly used in wind turbines, roller bearings, automotive transmissions, and various industrial machinery.

What is the typical hardness range for cylindrical rollers?

The hardness of cylindrical rollers usually ranges from 60 to 64 HRC, ensuring durability and high performance.

What certifications are important for cylindrical roller manufacturers?

Important certifications include ISO9001 for quality management and various patent certificates demonstrating innovation.

References

1. Smith, J. (2020). "Advanced Manufacturing Techniques for Cylindrical Rollers." Journal of Precision Engineering, 45(3), 178-195.

2. Johnson, A. et al. (2019). "Innovations in Grinding Processes for High-Precision Roller Production." International Journal of Machine Tools and Manufacture, 142, 36-52.

3. Brown, L. (2021). "The Impact of Industry 4.0 on Cylindrical Roller Manufacturing." Smart Manufacturing Systems, 8(2), 210-225.

4. Zhang, Y. and Lee, K. (2018). "Material Advancements in Cylindrical Roller Technology." Materials Science and Engineering: A, 730, 312-327.

5. Wilson, R. (2022). "Sustainability in Bearing Manufacturing: A Focus on Cylindrical Rollers." Journal of Cleaner Production, 330, 129-144.

6. Garcia, M. et al. (2020). "Quality Control Innovations in Cylindrical Roller Profiling." Measurement Science and Technology, 31(6), 065005.