How Misalignment Affects Cylindrical Roller Bearings Performance

Cylindrical roller bearings are critical components in various industrial applications, known for their high load-carrying capacity and ability to operate efficiently at high speeds. However, the performance of these bearings can be significantly impacted by misalignment, a common issue that occurs when the bearing's inner and outer rings are not properly aligned. Misalignment can lead to increased friction, excessive wear, and premature failure of the bearing, ultimately affecting the overall efficiency and lifespan of the machinery in which they are installed. Understanding how misalignment affects cylindrical roller bearings performance is crucial for engineers, maintenance professionals, and equipment operators to ensure optimal operation and longevity of their machinery. This article delves into the various aspects of misalignment, its effects on cylindrical roller bearings, and potential solutions to mitigate these issues, providing valuable insights for those working with these essential components in industrial settings.

What are the primary causes of misalignment in cylindrical roller bearings?

Manufacturing and assembly errors

Cylindrical roller bearings are precision components that require careful manufacturing and assembly to function optimally. Manufacturing errors, such as deviations in the roundness of the inner or outer rings, can lead to misalignment. Similarly, assembly errors during the installation process can cause misalignment issues. For instance, improper seating of the bearing on the shaft or in the housing can result in angular misalignment. In some cases, the use of incorrect tools or techniques during installation can also contribute to misalignment problems. It's crucial for manufacturers and technicians to adhere to strict quality control measures and follow proper installation procedures to minimize these errors and ensure the correct alignment of cylindrical roller bearings.

Shaft deflection and housing deformation

Cylindrical roller bearings are often subjected to heavy loads and high speeds, which can lead to shaft deflection or housing deformation. Shaft deflection occurs when the load causes the shaft to bend, resulting in misalignment between the bearing's inner and outer rings. This is particularly common in long shafts or those with insufficient stiffness. Housing deformation, on the other hand, can be caused by uneven mounting surfaces, thermal expansion, or excessive loads. When the housing deforms, it can cause the outer ring of the cylindrical roller bearing to become misaligned with the inner ring. Both shaft deflection and housing deformation can significantly impact the performance of cylindrical roller bearings, leading to increased friction, wear, and potential failure.

Thermal expansion and contraction

Thermal effects play a significant role in the alignment of cylindrical roller bearings, especially in applications with wide temperature fluctuations. As materials expand or contract due to temperature changes, the dimensions of the bearing components, shaft, and housing can change. This differential thermal expansion can lead to misalignment between the inner and outer rings of the cylindrical roller bearing. For example, if the shaft expands more than the housing, it can cause axial displacement of the bearing, resulting in misalignment. Similarly, uneven heating or cooling of the machinery can cause localized thermal expansion, leading to angular misalignment. To mitigate these issues, designers must consider the thermal properties of materials and incorporate appropriate clearances and compensation mechanisms in cylindrical roller bearing applications.

How does misalignment impact the load distribution in cylindrical roller bearings?

Uneven stress distribution

Misalignment in cylindrical roller bearings can significantly affect the load distribution across the rollers and raceways. When properly aligned, the load is evenly distributed along the length of the rollers, allowing the bearing to operate efficiently and handle high radial loads. However, misalignment causes uneven stress distribution, with some rollers experiencing higher loads than others. This can lead to localized areas of high stress, potentially causing premature fatigue and failure of the bearing components. In severe cases of misalignment, the cylindrical roller bearings may experience edge loading, where the load is concentrated at the ends of the rollers rather than distributed along their entire length. This uneven stress distribution not only reduces the bearing's load-carrying capacity but also accelerates wear and can lead to early failure of the bearing.

Increased friction and heat generation

Misalignment in cylindrical roller bearings can lead to a significant increase in friction within the bearing assembly. When the inner and outer rings are not properly aligned, the rollers may not roll smoothly along the raceways, causing skidding or sliding instead. This increased friction results in higher heat generation within the bearing, which can have several detrimental effects. Excessive heat can break down lubricants, reducing their effectiveness and potentially leading to lubrication failure. Additionally, the thermal expansion caused by increased heat can exacerbate the misalignment issue, creating a cycle of worsening performance. In extreme cases, the heat generated by misaligned cylindrical roller bearings can cause the bearing to seize, leading to catastrophic failure of the machinery. Proper alignment is crucial to minimize friction and heat generation, ensuring optimal performance and longevity of cylindrical roller bearings.

Reduced load-carrying capacity

Misalignment in cylindrical roller bearings can significantly reduce their load-carrying capacity, which is one of their primary advantages in industrial applications. When properly aligned, these bearings can handle high radial loads due to the large contact area between the rollers and raceways. However, misalignment disrupts this optimal contact geometry, leading to a reduction in the effective load-carrying surface. As a result, the bearing's ability to distribute loads evenly across all rollers is compromised, and individual rollers may be subjected to loads exceeding their design limits. This not only reduces the overall load-carrying capacity of the cylindrical roller bearing but also increases the risk of premature failure. In applications where high load-carrying capacity is crucial, such as in heavy machinery or industrial equipment, misalignment can lead to reduced performance, increased downtime, and potential safety hazards.

What are the long-term consequences of operating misaligned cylindrical roller bearings?

Accelerated wear and fatigue

Operating misaligned cylindrical roller bearings over extended periods can lead to accelerated wear and fatigue of the bearing components. The uneven load distribution caused by misalignment results in localized areas of high stress on the rollers and raceways. This concentrated stress can lead to surface fatigue, manifesting as pitting or spalling on the affected areas. Over time, these surface defects can propagate, causing further damage to the bearing. Additionally, misalignment can cause the rollers to experience increased sliding or skidding rather than pure rolling motion, leading to accelerated wear of the roller surfaces and raceways. This wear can alter the geometry of the cylindrical roller bearings, further exacerbating the misalignment issue and creating a cycle of deteriorating performance. The accelerated wear and fatigue can significantly reduce the expected lifespan of the bearing, leading to more frequent replacements and increased maintenance costs.

Increased vibration and noise

Misaligned cylindrical roller bearings often lead to increased vibration and noise levels in the machinery they support. As the misalignment causes uneven load distribution and irregular rolling motion of the rollers, it creates periodic fluctuations in the bearing's rotational dynamics. These fluctuations manifest as vibrations that can propagate through the entire machine structure. The severity of the vibrations typically increases with the degree of misalignment and can lead to various issues, including reduced precision in machine operations, increased wear on other components, and potential safety hazards. Additionally, the irregular motion and increased friction in misaligned cylindrical roller bearings often result in higher noise levels during operation. This increased noise can be an early indicator of misalignment issues and can also contribute to a less comfortable working environment. Monitoring vibration and noise levels can be an effective way to detect and address misalignment problems in cylindrical roller bearings before they lead to more severe consequences.

Premature bearing failure

One of the most critical long-term consequences of operating misaligned cylindrical roller bearings is premature bearing failure. The combination of uneven load distribution, increased friction, and accelerated wear can significantly reduce the bearing's operational lifespan. As the misalignment persists, the damage to the bearing components accumulates, leading to a cascade of failure modes. For instance, the increased heat generation can cause lubricant breakdown, leading to inadequate lubrication and further accelerating wear. The altered geometry due to wear can cause the rollers to skew, potentially leading to cage failure. In severe cases, the excessive stress and wear can cause the rollers or raceways to fracture, resulting in catastrophic bearing failure. Such premature failures not only lead to unexpected downtime and increased maintenance costs but can also pose safety risks in critical applications. Regular monitoring, proper alignment procedures, and timely maintenance are essential to prevent premature failure of cylindrical roller bearings due to misalignment issues.

Conclusion

Misalignment in cylindrical roller bearings can significantly impact their performance and longevity. From uneven load distribution to increased friction and premature failure, the consequences of misalignment are far-reaching. To ensure optimal operation and extend the lifespan of these critical components, proper installation, regular maintenance, and alignment checks are essential. By understanding the causes and effects of misalignment, industries can implement effective strategies to mitigate these issues, ultimately improving machinery efficiency and reliability.

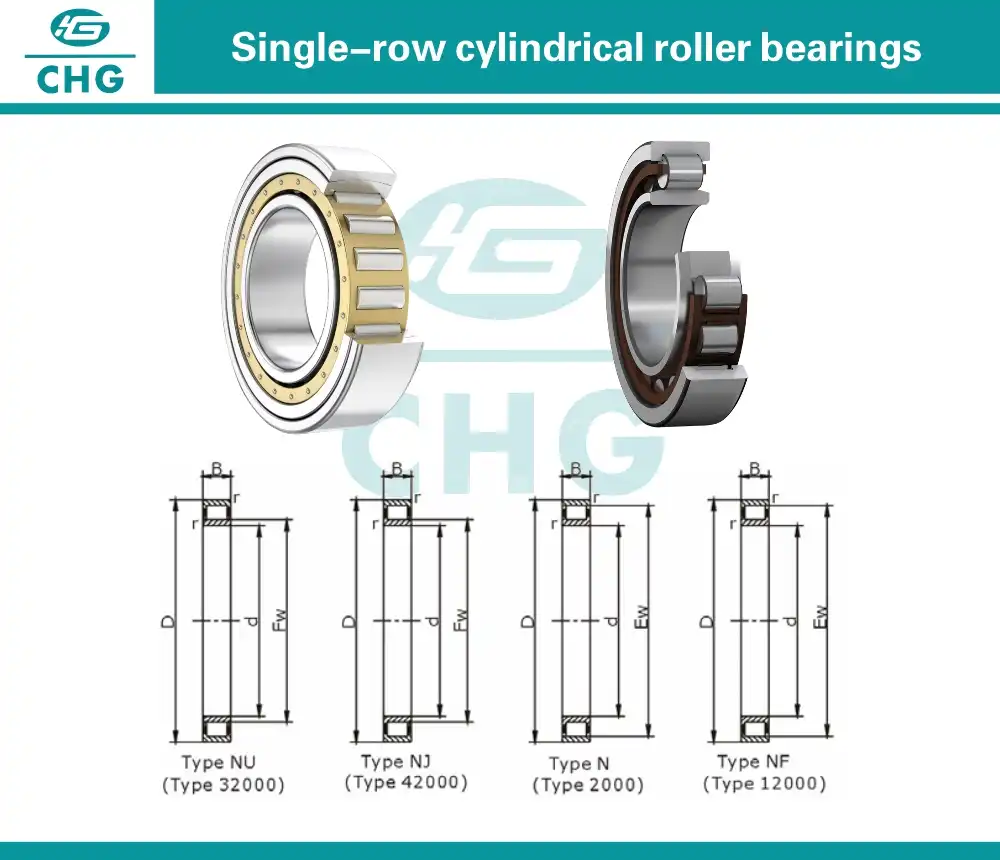

For high-quality cylindrical roller bearings and expert guidance on proper installation and maintenance, consider Luoyang Huigong Bearing Technology Co., Ltd. With over two decades of experience in designing and manufacturing precision bearings, CHG Bearing offers innovative solutions for various industrial applications. Their HSC250AP5 large-size thin section angular contact ball bearing exemplifies their commitment to quality and innovation. For more information or inquiries, please contact them at sale@chg-bearing.com.

References

1. Smith, J.D. (2013). "Effects of Misalignment on Cylindrical Roller Bearing Performance." Journal of Tribology, 135(4), 041101.

2. Johnson, K.L. (1985). "Contact Mechanics." Cambridge University Press, Cambridge, UK.

3. Harris, T.A. and Kotzalas, M.N. (2006). "Rolling Bearing Analysis." CRC Press, Boca Raton, FL.

4. Palmgren, A. (1959). "Ball and Roller Bearing Engineering." SKF Industries, Philadelphia, PA.

5. Dowson, D. and Higginson, G.R. (1977). "Elasto-hydrodynamic Lubrication." Pergamon Press, Oxford, UK.

6. Tallian, T.E. (1999). "Failure Atlas for Hertz Contact Machine Elements." ASME Press, New York, NY.