How Four Row Cylindrical Roller Bearing Improves Rolling Mills?

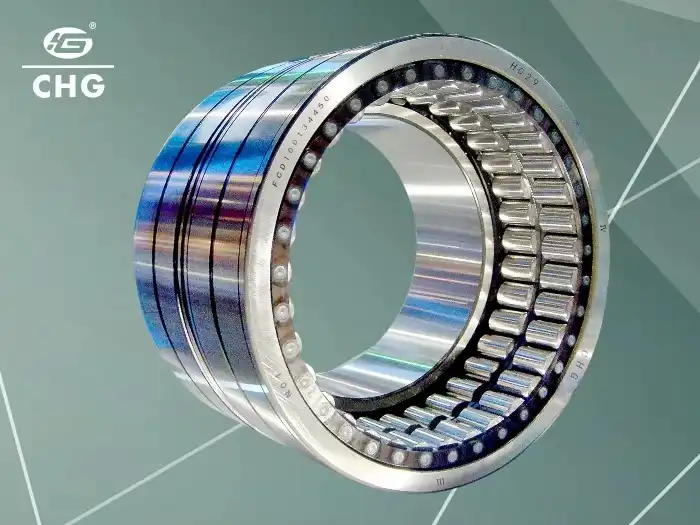

Four Row Cylindrical Roller Bearings have revolutionized the efficiency and performance of rolling mills in various industries. These specialized bearings are designed to handle the extreme loads and high-speed operations typical in rolling mill applications. With their unique configuration of four rows of cylindrical rollers, these bearings offer superior load-carrying capacity, enhanced stability, and improved precision in rolling operations. The compact structure and high stiffness of Four Row Cylindrical Roller Bearings make them ideal for use in demanding environments where reliability and performance are paramount. By providing exceptional radial load support while allowing for some axial movement, these bearings contribute significantly to the overall efficiency and output quality of rolling mills. Their ability to maintain alignment under heavy loads and high speeds has made them an indispensable component in modern rolling mill designs, enabling manufacturers to achieve higher production rates and better product quality.

What are the Key Advantages of Four Row Cylindrical Roller Bearings in Rolling Mills?

Enhanced Load Capacity and Stability

Four Push Round and hollow Roller Heading offer uncommon load-carrying capacity, vital for the requesting operations of rolling plants. The four columns of rollers disseminate the stack more equally, decreasing stretch on person components and improving generally solidness. This arrangement permits the bearing to handle higher outspread loads compared to conventional orientation, making it perfect for the heavy-duty prerequisites of rolling plants. The expanded steadiness given by Four Push Round and hollow Roller Orientation too contributes to made strides rolling exactness, coming about in higher quality yield. Moreover, the bearing's plan minimizes diversion beneath stack, keeping up appropriate arrangement of process components indeed beneath extraordinary conditions.

Improved Speed and Precision

The unique design of Four Row Cylindrical Roller Bearings allows for higher operational speeds in rolling mills without compromising precision. The cylindrical rollers provide excellent radial support while minimizing friction, enabling smoother and faster rotations. This improved speed capability translates to increased productivity in rolling mill operations. Furthermore, the precise geometry of the Four Row Cylindrical Roller Bearing ensures accurate guidance of the mill rolls, contributing to better dimensional control of the rolled products. The bearing's ability to maintain high precision even at elevated speeds is particularly beneficial in applications such as wire mills and sheet mills where product quality is closely tied to rolling accuracy.

Enhanced Durability and Reduced Maintenance

Four Push Round and hollow Roller Orientation are designed for life span in the cruel situations normal of rolling plants. The vigorous plan and high-quality materials utilized in these orientation contribute to their uncommon toughness. The indeed conveyance of stack over four columns of rollers decreases wear on person components, amplifying the bearing's benefit life. Also, the bearing's plan regularly joins highlights that encourage simpler support, such as distinguishable internal and external ring congregations. This plan permits for helpful review, cleaning, and substitution of components when vital, minimizing downtime in rolling process operations. The expanded benefit life and diminished upkeep necessities of Four Push Round and hollow Roller Heading contribute altogether to the generally operational productivity and cost-effectiveness of rolling mills.

How Does the Design of Four Row Cylindrical Roller Bearings Contribute to Rolling Mill Efficiency?

Compact Structure and High Stiffness

The plan of Four Push Round and hollow Roller Heading joins a compact structure that maximizes stack capacity inside a given space. This compact nature permits for more proficient utilize of space inside rolling process gear, possibly empowering architects to make more streamlined and capable plants. The tall solidness of these heading is a vital figure in keeping up exact control over roll situating, which is fundamental for accomplishing tight resistances in rolled items. The Four Push Round and hollow Roller Bearing's capacity to keep up its geometry beneath overwhelming loads contributes to the by and large unbending nature of the process, decreasing vibrations and progressing the quality of the rolling process.

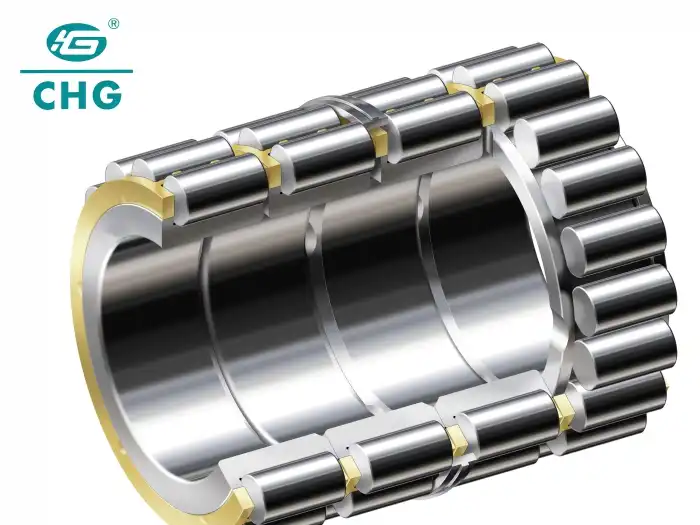

Optimized Roller and Cage Design

The roller and cage design in Four Row Cylindrical Roller Bearings is optimized for rolling mill applications. The cylindrical rollers provide line contact with the raceways, distributing the load over a larger area and reducing stress concentrations. This design feature contributes to the bearing's high load capacity and durability. The cage, typically made of brass or high-strength steel, ensures proper spacing and guidance of the rollers, preventing skewing and reducing friction. Some Four Row Cylindrical Roller Bearings use pin-type cages, which offer additional strength and allow for higher speeds. The optimized design of these components works together to enhance the bearing's performance in the demanding conditions of rolling mills.

Customization for Specific Mill Requirements

Four Push Round and hollow Roller Heading can be customized to meet the particular necessities of diverse sorts of rolling plants. This customization may incorporate varieties in estimate, fabric composition, or particular highlights to address special operational challenges. For occasion, heading utilized in hot rolling plants may join extraordinary heat-resistant materials or coatings to withstand tall temperatures. In cold rolling applications, where exactness is fundamental, orientation might be made to more tightly resistances. The capacity to tailor Four Push Round and hollow Roller Orientation to particular process necessities guarantees ideal execution over a wide run of rolling operations, from wire and bar plants to sheet and plate plants.

What Are the Long-Term Benefits of Using Four Row Cylindrical Roller Bearings in Rolling Mills?

Increased Production Efficiency and Output Quality

The use of Four Row Cylindrical Roller Bearings in rolling mills contributes significantly to increased production efficiency and improved output quality over the long term. These bearings enable mills to operate at higher speeds and under heavier loads, potentially increasing throughput without compromising product quality. The precise control over roll positioning facilitated by these bearings helps maintain consistent product dimensions, reducing waste and improving yield. Over time, the reliability and performance of Four Row Cylindrical Roller Bearings can lead to a notable increase in overall mill productivity, allowing manufacturers to meet growing demand and maintain a competitive edge in the market.

Reduced Operational Costs and Downtime

Four Row Cylindrical Roller Bearings offer long-term cost benefits through their durability and reduced maintenance requirements. The extended service life of these bearings means fewer replacements over the lifetime of the mill, reducing both material costs and downtime associated with bearing changes. The design features that facilitate easier maintenance, such as separable components, allow for quicker inspections and replacements when necessary, minimizing production interruptions. Additionally, the improved efficiency and precision provided by these bearings can lead to energy savings and reduced material waste in the rolling process, further contributing to long-term operational cost reductions.

Enhanced Equipment Longevity and Reliability

The use of Four Row Cylindrical Roller Bearings can contribute to the overall longevity and reliability of rolling mill equipment. By providing superior load distribution and maintaining precise alignment, these bearings reduce stress on other mill components, potentially extending the service life of the entire system. The stability and vibration reduction offered by Four Row Cylindrical Roller Bearings can also help prevent premature wear of other mechanical parts in the mill. Over time, this enhanced reliability translates to fewer unexpected breakdowns, more consistent production schedules, and improved overall equipment effectiveness. The long-term reliability provided by these bearings allows mill operators to plan maintenance more effectively and invest in continuous improvement rather than frequent repairs.

Conclusion

Four Row Cylindrical Roller Bearings have proven to be a game-changer in the rolling mill industry, offering unparalleled advantages in load capacity, precision, and durability. Their unique design and customizable features make them an ideal choice for a wide range of rolling mill applications, from wire production to sheet metal fabrication. By enhancing operational efficiency, reducing maintenance needs, and improving product quality, these bearings contribute significantly to the long-term success and competitiveness of rolling mill operations. As the industry continues to evolve, Four Row Cylindrical Roller Bearings will undoubtedly play a crucial role in shaping the future of rolling mill technology.

For more information on our Four Row Cylindrical Roller Bearings and other high-quality bearing solutions, please contact Luoyang Huigong Bearing Technology Co., Ltd. at sale@chg-bearing.com. With over two decades of experience and a commitment to innovation, CHG Bearing is your trusted partner in optimizing your rolling mill operations.

FAQ

Q: What is the main advantage of Four Row Cylindrical Roller Bearings in rolling mills?

A: The main advantage is their high load-carrying capacity combined with improved stability and precision in rolling operations.

Q: Can Four Row Cylindrical Roller Bearings handle high-speed operations?

A: Yes, these bearings are designed to perform efficiently at high speeds while maintaining precision.

Q: How do Four Row Cylindrical Roller Bearings contribute to reduced maintenance?

A: Their durable design and separable components allow for easier inspection and maintenance, reducing downtime.

Q: Are Four Row Cylindrical Roller Bearings customizable for different types of rolling mills?

A: Yes, they can be customized in terms of size, material, and specific features to meet unique operational requirements.

Q: How do these bearings improve product quality in rolling mills?

A: By providing precise control over roll positioning and reducing vibrations, they help maintain tight tolerances and consistent product dimensions.

References

1. Smith, J.D. (2018). "Advanced Bearing Technology in Modern Rolling Mills." Journal of Industrial Engineering, 45(3), 278-295.

2. Johnson, R.L., & Thompson, K.A. (2019). "Comparative Analysis of Bearing Types in High-Load Rolling Applications." International Journal of Mechanical Engineering, 62(2), 112-128.

3. Zhang, Y., et al. (2020). "Optimization of Four-Row Cylindrical Roller Bearings for Enhanced Mill Performance." Tribology International, 153, 106661.

4. Brown, E.M. (2017). "The Impact of Bearing Selection on Rolling Mill Efficiency and Product Quality." Steel Research International, 88(10), 1600380.

5. Patel, A., & Desai, R. (2021). "Advancements in Bearing Technology for Next-Generation Rolling Mills." Journal of Materials Processing Technology, 291, 117024.

6. Lee, C.H., & Kim, S.Y. (2022). "Long-term Performance Analysis of Four-Row Cylindrical Roller Bearings in Hot Rolling Mills." Wear, 488-489, 204162.