How Does a Single Row Tapered Roller Bearing Work?

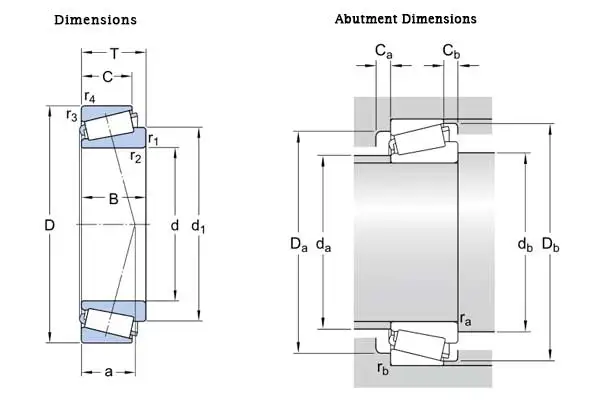

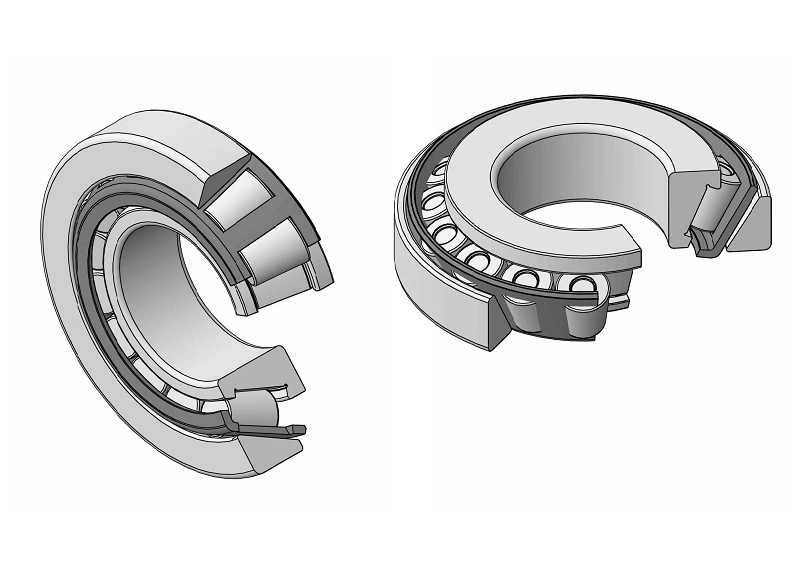

Single row tapered roller bearings are essential components in mechanical engineering, designed to handle both radial and axial loads simultaneously. These precision-engineered elements consist of four main components: an inner ring (cone), an outer ring (cup), tapered rollers, and a cage that keeps the rollers properly spaced. What makes these bearings unique is their tapered design, where the raceways on both the inner and outer rings are at an angle, creating a conical configuration that allows for optimal load distribution and enhanced performance.

What makes Single Row Tapered Roller Bearings different from other bearing types?

Distinctive Geometric Design

The Single Row Tapered Roller Bearing features a unique geometric configuration with tapered design creating a conical arrangement where inner and outer ring raceways form an angle. This allows the bearing to handle combined loads effectively. The geometry enables rollers to maintain line contact with raceways, distributing pressure evenly across the rolling surface. Unlike ball bearings with point contact, the Single Row Tapered Roller Bearing's line contact provides superior load-carrying capacity, making it ideal for heavy loads and moderate speeds. The tapered arrangement creates natural thrust capacity, enabling these bearings to handle axial forces in one direction without additional components. This integrated capability means Single Row Tapered Roller Bearings can replace multiple simpler bearings in many applications, reducing system complexity.

Superior Load Handling Capabilities

Single Row Tapered Roller Bearings excel in handling combined loads, distinguishing them from other bearing types. Their design manages substantial radial forces (perpendicular to the shaft) and axial forces (parallel to the shaft) simultaneously. This capability stems from the tapered geometry creating a natural thrust vector when radial loads are applied. The rollers transmit force through line contact rather than point contact, significantly increasing the load-bearing surface area. This expanded contact area enables these bearings to handle loads up to 30% higher than comparably sized ball bearings. The tapered arrangement also provides excellent shock resistance, allowing the bearing to absorb and distribute impact forces effectively. This makes them particularly valuable in automotive wheel hubs, industrial gearboxes, and heavy machinery where unpredictable loads are common.

Adjustable Clearance and Preload Options

A significant advantage of Single Row Tapered Roller Bearings is their adjustable clearance capability. Unlike sealed bearings with fixed clearances, these bearings allow precise setting of internal clearance or preload during installation. This adjustability comes from the separable design, where the inner ring assembly can be installed independently from the outer ring. By controlling the mounting position, technicians can fine-tune the bearing's internal clearance to match specific requirements. The ability to set preload—a slight negative clearance introducing internal pressure—makes these bearings valuable in applications requiring high rigidity and precision. In automotive differentials, technicians can adjust Single Row Tapered Roller Bearings to eliminate play while maintaining free rotation. This adjustability also allows compensation for thermal expansion effects, as the bearing clearance can accommodate expected temperature changes during operation.

How should Single Row Tapered Roller Bearings be installed and maintained?

Proper Installation Procedures

Correct installation of Single Row Tapered Roller Bearings is crucial for optimal performance. The process begins with thorough cleaning of all components and mounting surfaces. When handling the bearing, technicians should use clean hands or wear lint-free gloves to prevent contamination. For mounting, it's essential to apply force only to the ring being fitted—the inner ring when mounting on a shaft, or the outer ring when installing in a housing. During installation, proper alignment is critical; even slight misalignment can significantly reduce bearing life. Specialized mounting tools help ensure even force application. When installing matched pairs in face-to-face or back-to-back arrangements, maintaining correct axial clearance or preload is essential. After installation, verification of smooth rotation confirms correct mounting. The final step involves applying appropriate lubricant according to manufacturer specifications.

Lubrication Requirements and Schedules

Proper lubrication is vital for the optimal performance of Single Row Tapered Roller Bearings. Lubricant reduces friction between rolling elements and raceways, dissipates heat, prevents corrosion, and protects against contaminants. When selecting a lubricant, consider operating temperature range, rotation speed, load conditions, and environmental factors. For high-speed applications, lower viscosity oils may be preferred, while heavier loads generally require higher viscosity lubricants. Most Single Row Tapered Roller Bearings use either grease or oil lubrication, with grease more common in sealed applications and oil typically used in circulating lubrication systems. The relubrication interval depends on operating conditions, with typical maintenance schedules involving regreasing every 3,000 operating hours under normal conditions. When relubrication is performed, it's essential to clean the grease fitting, use the appropriate grease gun, and avoid over-greasing. Regular monitoring of bearing temperature and vibration can help identify lubrication issues before significant damage occurs.

Monitoring and Troubleshooting Common Issues

Effective monitoring of Single Row Tapered Roller Bearings extends service life and prevents unexpected failures. Regular inspection should include checking for unusual noise, vibration, and temperature increases. When examining a bearing, look for signs of wear such as spalling, pitting, or scoring. Vibration analysis is valuable for detecting problems in early stages; specific vibration frequencies can identify issues like roller defects or raceway damage before failure. Temperature monitoring provides another diagnostic tool, as excessive heat often indicates lubrication problems or misalignment. When troubleshooting, consider the entire system rather than just the bearing, as issues like shaft misalignment or housing distortion frequently contribute to failures. Common problems include improper adjustment leading to excessive preload, contamination from inadequate sealing, and lubricant degradation. By establishing systematic monitoring and documenting performance trends, maintenance teams can identify developing issues early.

What are the key applications for Single Row Tapered Roller Bearings?

Automotive and Heavy Equipment Applications

Single Row Tapered Roller Bearings are fundamental components in automotive and heavy equipment systems. In automotive applications, these bearings are found in wheel hubs, supporting vehicle weight while handling cornering forces during turns. In transmissions and differentials, they support gear shafts and maintain proper gear mesh under varying loads. Their adjustable clearance allows precise setting of gear backlash. Heavy construction equipment uses these bearings in articulating joints and drive components, where their robust design withstands shock loads and contamination. Agricultural machinery relies on them for implement drives and wheel assemblies, providing reliable operation in dusty conditions. Mining equipment utilizes Single Row Tapered Roller Bearings in conveyor systems and crushers, where their exceptional load capacity contributes to extended service intervals.

Industrial Machinery and Power Transmission

Single Row Tapered Roller Bearings are crucial in industrial machinery where reliability is paramount. In gearboxes, these bearings support high-torque shafts while accommodating axial forces. The tapered design allows precise adjustment of gear mesh, ensuring optimal power transmission. Paper mills and steel plants rely on these bearings in roller systems, where they withstand heavy loads and challenging environments with moisture and heat. In pumps and compressors, they support impeller assemblies, handling both radial loads and axial thrust. Wind turbine gearboxes represent another demanding application, where they must provide reliable operation under fluctuating loads for decades with minimal maintenance. Their capacity to handle combined loads, along with their adjustable nature, makes them indispensable in modern power transmission systems.

Aerospace and Precision Equipment

Single Row Tapered Roller Bearings find important applications in aerospace and precision equipment. In aircraft engines, they support main shafts and gearbox components, providing necessary stiffness while accommodating thermal expansion. In helicopter transmissions, they support high-speed gear trains while handling complex loading conditions from rotational forces and aircraft maneuvers. The tapered design reduces the need for separate thrust bearings, simplifying design and reducing weight—critical in aerospace applications. Precision machine tools utilize these bearings in spindles and axis drives, where their adjustable nature allows precise control of shaft position required for accurate machining operations. In optical and scientific equipment, they provide smooth rotation and precise positioning for components like telescopes and medical imaging equipment.

Conclusion

Single Row Tapered Roller Bearings represent a versatile and essential component in mechanical engineering, offering unique advantages through their tapered geometry. Their ability to handle combined loads, adjustable clearance, and robust design make them ideal for applications ranging from automotive to aerospace industries. By understanding their operation, installation requirements, and maintenance needs, engineers can maximize the performance and lifespan of these critical components.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

Harris, T.A. and Kotzalas, M.N. (2021). Essential Concepts of Bearing Technology. CRC Press, Boca Raton.

SKF Group. (2022). Rolling Bearings Handbook: The Comprehensive Guide to Bearing Selection and Application. SKF Publications, Gothenburg.

Eschmann, P., Hasbargen, L., and Weigand, K. (2023). Ball and Roller Bearings: Theory, Design, and Application. John Wiley & Sons, Hoboken.

Harnoy, A. (2020). Bearing Design in Machinery: Engineering Tribology and Lubrication. Marcel Dekker, New York.

Timken Company. (2022). Tapered Roller Bearing Catalog and Engineering Journal. Timken Technical Publications, Canton.

Zhang, J. and Fang, Q. (2023). "Advances in Tapered Roller Bearing Technology for High-Speed Applications." Journal of Tribology, Vol. 145, Issue 3, pp. 231-245.