How Do You Choose the Right Conical Bearing for Your Machine?

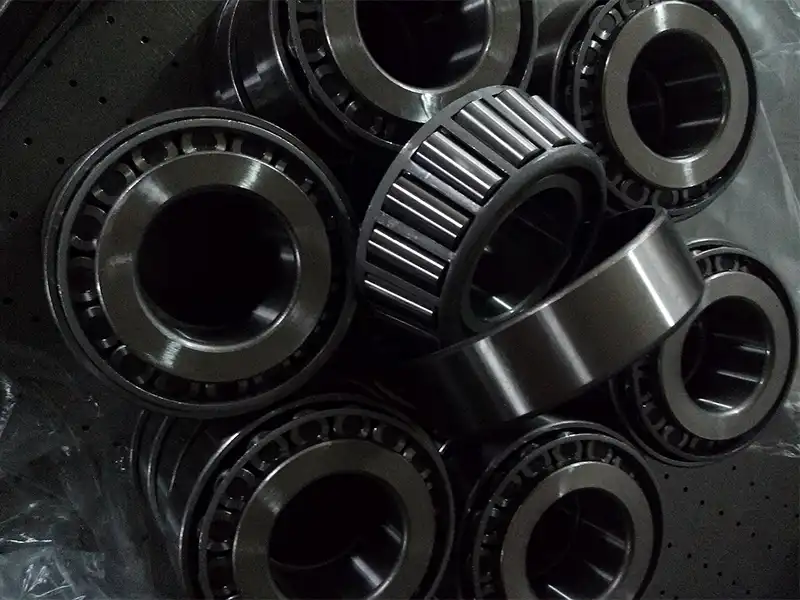

Conical bearings, also known as tapered roller bearings, are critical components in numerous mechanical systems, playing a pivotal role in supporting heavy loads and managing complex engineering challenges. Selecting the appropriate conical bearing is not merely a technical decision but a strategic choice that can significantly impact machine performance, efficiency, and longevity. This comprehensive guide will walk you through the intricate process of identifying, evaluating, and selecting the ideal conical bearing for your specific mechanical requirements.

What Makes Conical Bearings Unique in Machine Design?

Conical bearings represent a sophisticated engineering solution designed to handle both radial and axial loads simultaneously, making them indispensable in diverse industrial applications. Their distinctive tapered roller configuration allows for superior load distribution, reduced friction, and enhanced mechanical performance across multiple operational scenarios.

The fundamental engineering principle behind conical bearings lies in their geometry. Unlike traditional cylindrical bearings, these specialized components feature rollers that are machined with a precise taper, enabling them to accommodate complex load vectors. This unique design translates into remarkable load-bearing capabilities, making them instrumental in high-precision machinery such as automotive transmissions, industrial gearboxes, and aerospace mechanisms.

The structural integrity of conical bearings stems from their ability to manage angular contact between rolling elements and raceways. By distributing mechanical stress across a larger surface area, these bearings minimize localized wear and potential failure points. Engineers and designers appreciate their versatility, as they can be mounted in various configurations – single, double, or tandem – to meet specific mechanical requirements.

When examining the microscopic interactions within a conical bearing, one observes a sophisticated dance of engineering principles. The tapered rollers generate line contact rather than point contact, which significantly enhances load-bearing capacity and reduces stress concentration. This design philosophy enables conical bearings to withstand substantial radial, axial, and combined loads while maintaining exceptional precision and minimal friction.

Industrial sectors ranging from automotive manufacturing to heavy machinery rely extensively on these remarkable components. Their ability to handle misalignment, compensate for thermal expansion, and provide reliable performance under challenging conditions makes them a cornerstone of modern mechanical design. The selection process involves understanding not just the bearing's physical characteristics, but also its potential interactions within complex mechanical systems.

How Can You Assess Load Requirements for Conical Bearings?

Load assessment represents the cornerstone of selecting an appropriate conical bearing, requiring a meticulous evaluation of multiple mechanical parameters. Understanding the intricate relationship between load types, magnitudes, and bearing capabilities demands a systematic approach that combines theoretical knowledge with practical engineering insights.

The first critical step in load assessment involves categorizing the anticipated loads your specific application will encounter. Mechanical engineers typically distinguish between three primary load types: radial loads, which act perpendicular to the shaft's rotational axis; axial loads, which parallel the shaft's centerline; and combined loads that involve simultaneous radial and axial force vectors.

Dynamic load capacity emerges as a fundamental consideration during this assessment. Manufacturers provide comprehensive rating tables that outline a bearing's capability to withstand specific load magnitudes over projected operational lifespans. These ratings incorporate sophisticated calculations involving material properties, geometric configurations, and anticipated stress distributions.

Precision becomes paramount when quantifying load requirements. Advanced computational methods, including finite element analysis and predictive modeling, enable engineers to simulate complex load scenarios with remarkable accuracy. These techniques allow for nuanced understanding of potential stress points, potential fatigue mechanisms, and overall bearing performance under diverse operational conditions.

Mathematical modeling plays a crucial role in load assessment. Engineers utilize specialized formulas such as the dynamic load rating (C) and static load rating (C0) to determine a bearing's suitability for specific applications. These calculations consider factors like roller geometry, material composition, and anticipated operational environments, providing a quantitative framework for bearing selection.

Temperature considerations represent another critical dimension of load assessment. Elevated temperatures can dramatically alter material properties, potentially compromising bearing performance. Sophisticated thermal management strategies, including specialized lubricants and advanced cooling mechanisms, help mitigate potential thermal-induced degradation.

Real-world application scenarios demand holistic load assessment strategies. Industries like aerospace, automotive manufacturing, and precision machinery require bearing selections that account for extreme operational variabilities. This necessitates comprehensive testing protocols, including accelerated life testing, thermal cycling, and simulated stress evaluations.

What Factors Influence Conical Bearing Longevity and Performance?

The longevity and performance of conical bearings are influenced by a complex interplay of material science, engineering design, and operational conditions. Understanding these multifaceted factors requires a sophisticated approach that transcends traditional mechanical engineering paradigms.

Material selection represents the foundational element determining bearing performance. High-grade bearing steels, typically containing chromium, molybdenum, and carefully controlled carbon concentrations, provide exceptional wear resistance and structural integrity. Advanced metallurgical processes like vacuum degassing and precision heat treatment further enhance material characteristics, enabling bearings to withstand extreme operational conditions.

Lubrication emerges as a critical factor governing bearing longevity. Sophisticated lubricant formulations, developed through advanced chemical engineering, create protective molecular films that minimize friction, dissipate heat, and prevent premature wear. Synthetic lubricants with nano-engineered additives offer superior performance compared to traditional mineral-based alternatives, extending operational lifespans and maintaining consistent mechanical performance.

Precision manufacturing techniques play a pivotal role in determining bearing quality. Computer numerical control (CNC) machining, coupled with advanced metrology systems, enables manufacturers to achieve microscopic tolerances that were historically unattainable. These technological advances translate into bearings with exceptional roundness, minimal surface irregularities, and consistent dimensional accuracy.

Environmental considerations significantly impact bearing selection and performance. Factors such as ambient temperature, humidity, potential contaminant exposure, and operational frequencies necessitate specialized bearing designs. Corrosion-resistant coatings, advanced sealing technologies, and engineered surface treatments help mitigate potential degradation mechanisms.

Maintenance strategies represent another crucial dimension influencing bearing performance. Predictive maintenance techniques, leveraging technologies like vibration analysis, infrared thermography, and acoustic emissions monitoring, enable proactive identification of potential failure mechanisms. These advanced diagnostic approaches facilitate timely interventions, minimizing unexpected downtime and extending operational lifecycles.

The intersection of material science, mechanical engineering, and computational modeling continues to drive innovation in conical bearing design. Emerging technologies like adaptive smart bearings, incorporating embedded sensors and self-diagnostic capabilities, promise to revolutionize traditional maintenance paradigms.

Conclusion

Selecting the right conical bearing requires a holistic approach that integrates sophisticated engineering principles, advanced computational techniques, and comprehensive understanding of operational contexts. By meticulously evaluating load requirements, material properties, and performance characteristics, engineers can make informed decisions that optimize mechanical system reliability and efficiency.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting CHG at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Hamrock, B. J., Schmid, S. R., & Jacobson, B. O. (2004). Fundamentals of Machine Elements. McGraw-Hill Education.

2. Harris, T. A., & Kotzalas, M. N. (2006). Rolling Bearing Analysis: Essential Concepts of Bearing Technology. CRC Press.

3. Eschmann, P., Hasbargen, L., & Weigand, K. (1985). Ball and Roller Bearings: Theory, Design and Application. John Wiley & Sons.

4. Booker, J. D., Swift, K. G., & Rowe, P. H. (2001). Design Consideration in Mechanical Transmission Systems. Butterworth-Heinemann.

5. Dowson, D. (1998). History of Tribology. Professional Engineering Publishing.

6. Stachowiak, G. W., & Batchelor, A. W. (2013). Engineering Tribology. Butterworth-Heinemann.

7. Menezes, P. L., Lovell, M. R., & Dahotre, N. B. (2013). Tribology of Advanced Materials: Toward Green Tribology. CRC Press.

8. Khonsari, M. M., & Booser, E. R. (2017). Applied Tribology: Bearing Design and Lubrication. John Wiley & Sons.

9. Roylance, B. J. (2001). Lubrication and Lubricants. Elsevier Science.

10. Jones, W. R. (2010). Bearing Design in Machinery: Engineering Tribology. Marcel Dekker.