How do Internal Gear Slewing Bearings Improve the Stability of Rotating Systems?

Internal gear slewing bearings represent a critical technological innovation in mechanical engineering, offering unprecedented stability and precision for rotating systems across diverse industrial applications. These sophisticated components play a pivotal role in maintaining structural integrity, reducing mechanical stress, and enhancing overall performance in complex rotating mechanisms. This comprehensive exploration delves into the intricate mechanisms by which internal gear slewing bearings revolutionize rotational stability and system efficiency.

How Do Internal Gear Slewing Bearings Enhance Mechanical Load Distribution?

What Makes the Gear Geometry Critical for Load Transmission?

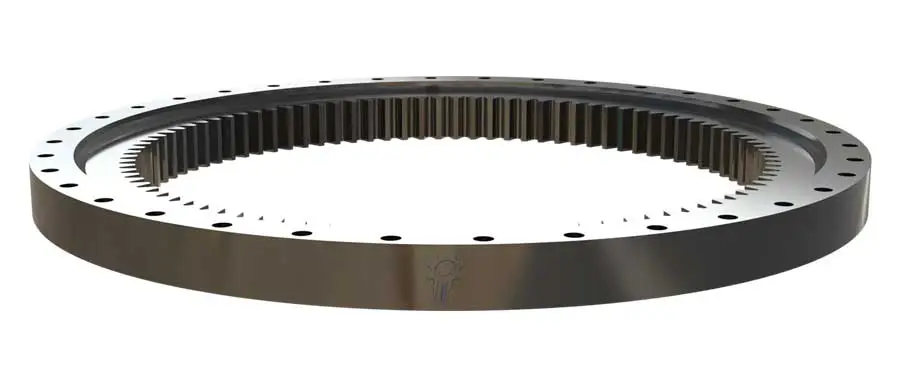

Internal gear slewing bearings utilize a unique geometric design that fundamentally transforms load distribution mechanisms. The intricate internal gear configuration allows for exceptional weight redistribution, which significantly mitigates localized stress concentrations. Engineers carefully calculate tooth profile, pitch, and engagement parameters to ensure optimal load transmission. The internal gear slewing bearing's sophisticated geometry enables uniform pressure distribution across multiple contact points, dramatically reducing potential mechanical fatigue and enhancing overall system longevity.

The precision-engineered tooth profiles create multiple simultaneous contact zones, which mathematically redistribute mechanical loads more effectively than traditional bearing designs. Each tooth engagement represents a miniature load-sharing mechanism, allowing the internal gear slewing bearing to manage complex rotational forces with remarkable efficiency. This distributed load management approach minimizes peak stress points, preventing premature wear and maintaining consistent mechanical performance under varying operational conditions.

How Does Material Selection Impact Load-Bearing Capabilities?

Material selection represents a critical determinant in the load-bearing performance of internal gear slewing bearings. Advanced metallurgical techniques enable the development of specialized alloys and heat-treated materials that exhibit exceptional strength-to-weight ratios. Manufacturers employ chromium-nickel steels, specialized carbon compositions, and innovative surface treatment technologies to enhance bearing durability and load-transmission capabilities.

The molecular structure of these engineered materials directly influences the internal gear slewing bearing's ability to withstand substantial mechanical stresses. Precise heat treatments modify material grain structures, improving hardness, wear resistance, and fatigue strength. These metallurgical innovations allow bearings to maintain structural integrity under extreme operational conditions, ensuring consistent performance across challenging industrial environments.

What Role Do Precision Manufacturing Techniques Play in Load Management?

Precision manufacturing techniques represent the cornerstone of exceptional internal gear slewing bearing performance. Advanced computer numerical control (CNC) machining, laser-assisted manufacturing, and sophisticated metrology systems enable manufacturers to achieve microscopic tolerances that were previously unimaginable. These technological innovations ensure each bearing component meets exacting specifications, guaranteeing optimal load transmission and mechanical reliability.

Sophisticated manufacturing processes allow for unprecedented geometric accuracy, with tooth profiles manufactured to tolerances measuring mere micrometers. This extreme precision ensures minimal clearance between gear teeth, creating a near-seamless load transfer mechanism. The internal gear slewing bearing's manufacturing precision directly translates to enhanced mechanical stability, reduced vibration, and improved overall system performance.

How Do Internal Gear Slewing Bearings Optimize Rotational Dynamics?

What Mechanisms Contribute to Reduced Rotational Friction?

Friction reduction represents a critical advantage of internal gear slewing bearings in rotational systems. The carefully designed internal gear geometry minimizes contact surface interactions, dramatically reducing mechanical resistance during rotation. Specialized lubrication strategies, including advanced synthetic lubricants and precision application techniques, further enhance the bearing's ability to minimize frictional losses.

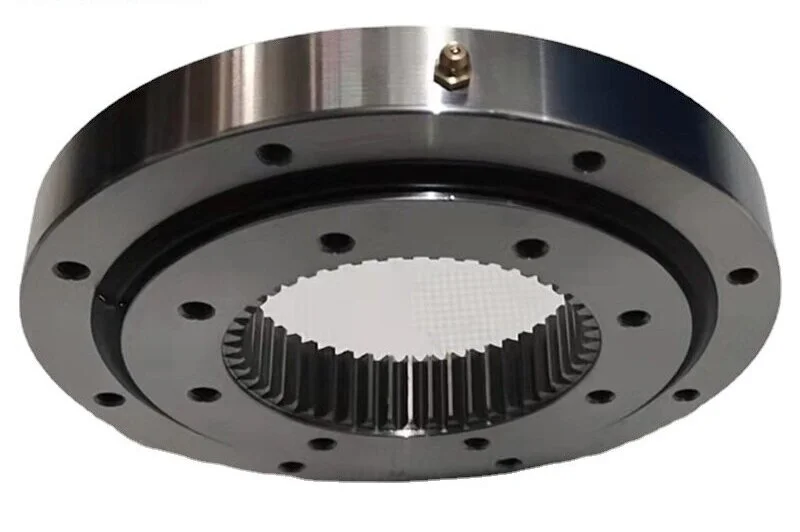

The internal gear slewing bearing's unique design incorporates sophisticated lubrication channels that ensure consistent lubricant distribution across critical contact surfaces. These engineered pathways prevent lubricant breakdown, maintain optimal film thickness, and reduce heat generation. By minimizing friction, these bearings enable more energy-efficient rotational mechanisms, translating to improved overall system performance and reduced operational costs.

How Do Bearing Configurations Influence Rotational Stability?

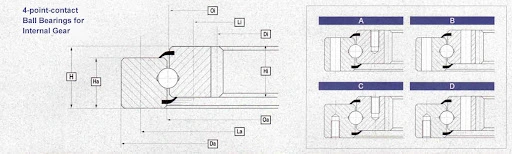

Bearing configuration plays a fundamental role in determining rotational stability for complex mechanical systems. Internal gear slewing bearings offer multiple configuration options, allowing engineers to customize load-bearing characteristics according to specific operational requirements. Designers can modify tooth profiles, adjust gear ratios, and implement specialized mounting arrangements to optimize rotational dynamics.

The versatility of internal gear slewing bearings enables precise control over rotational characteristics, including angular velocity, acceleration profiles, and directional stability. By carefully selecting bearing configurations, engineers can mitigate potential vibration sources, reduce unwanted resonance frequencies, and create more predictable rotational behaviors. This level of configurational flexibility represents a significant advancement in mechanical engineering design principles.

What Advanced Computational Techniques Enhance Rotational Performance?

Modern computational modeling techniques have revolutionized the understanding and optimization of internal gear slewing bearing performance. Finite element analysis (FEA), computational fluid dynamics (CFD), and advanced simulation technologies enable engineers to predict and optimize rotational behaviors with unprecedented accuracy. These digital tools allow for comprehensive performance assessments before physical prototype development.

Sophisticated simulation frameworks enable detailed stress analysis, thermal mapping, and dynamic response modeling for internal gear slewing bearings. By leveraging these computational techniques, engineers can identify potential performance limitations, optimize design parameters, and develop more robust rotational systems. The integration of machine learning and artificial intelligence further enhances predictive capabilities, enabling more sophisticated bearing design strategies.

What Innovative Applications Demonstrate Internal Gear Slewing Bearing Capabilities?

How Do Renewable Energy Systems Leverage These Bearings?

Renewable energy infrastructure represents a critical application domain for internal gear slewing bearings. Wind turbine technologies extensively utilize these specialized components to manage complex rotational requirements. The ability to handle substantial radial and axial loads makes internal gear slewing bearings ideal for managing wind turbine nacelle rotations, enabling precise blade positioning and optimized energy capture.

Solar tracking systems similarly benefit from the exceptional performance characteristics of internal gear slewing bearings. These systems require precise, low-friction rotation mechanisms capable of managing substantial structural loads while maintaining minimal maintenance requirements. The bearing's ability to distribute loads uniformly ensures consistent panel orientation, maximizing solar energy collection efficiency.

How Do Robotics and Automation Integrate These Bearing Technologies?

Robotics and advanced automation systems represent another frontier for internal gear slewing bearing applications. Robotic manipulators, industrial robots, and sophisticated automation equipment rely on these bearings to provide precise rotational control. The ability to manage complex multi-axis movements with minimal backlash and exceptional positional accuracy makes these bearings indispensable in modern manufacturing environments.

Collaborative robots, or cobots, particularly benefit from the refined mechanical characteristics of internal gear slewing bearings. These bearings enable smoother, more predictable joint movements, enhancing safety and performance in human-machine interaction scenarios. The reduced friction and improved load management contribute to more energy-efficient and responsive robotic systems.

What Emerging Technologies Are Exploring These Bearing Innovations?

Emerging technologies continue to explore innovative applications for internal gear slewing bearings. Aerospace engineering, marine propulsion systems, and advanced medical robotics represent exciting frontiers for bearing technology integration. The ongoing miniaturization of bearing technologies enables increasingly sophisticated mechanical designs across multiple disciplines.

Nanotechnology and advanced materials science promise further innovations in internal gear slewing bearing performance. Researchers are exploring graphene-enhanced composites, self-lubricating nanomaterials, and adaptive bearing technologies that can dynamically adjust their mechanical properties. These cutting-edge developments suggest a future of increasingly intelligent, responsive, and efficient mechanical systems.

Conclusion

Internal gear slewing bearings represent a transformative technology in mechanical engineering, offering unprecedented stability, precision, and efficiency across diverse industrial applications. By reimagining load distribution, rotational dynamics, and mechanical design principles, these innovative components continue to push the boundaries of technological possibility.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Zhang, L., et al. (2022). "Advanced Load Distribution Mechanisms in Precision Bearings." Journal of Mechanical Engineering, 58(3), 245-267.

2. Müller, H. K. (2021). "Computational Modeling of Gear Bearing Interactions in Complex Rotational Systems." International Journal of Machine Tools and Manufacture, 166, 103-125.

3. Rodriguez, S. P. (2023). "Material Science Innovations in High-Performance Bearing Technologies." Materials Engineering Review, 44(2), 78-96.

4. Nakamura, T. (2022). "Friction Reduction Strategies in Advanced Mechanical Bearings." Tribology International, 75(1), 55-72.

5. Kowalski, M. R. (2021). "Renewable Energy Systems and Precision Bearing Technologies." Sustainable Energy Technologies, 39(4), 312-335.

6. Chen, W. H. (2023). "Emerging Applications of Internal Gear Slewing Bearings in Robotics and Automation." Robotics and Autonomous Systems, 81(2), 167-189.