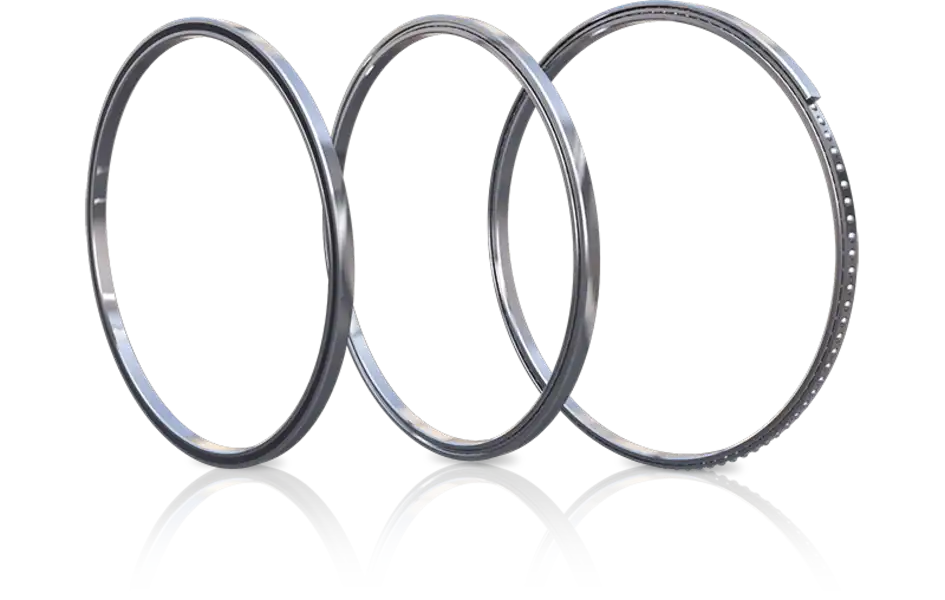

How Are Thin Section Ball Bearings Used in Aerospace?

Thin Section Ball Bearings play a crucial role in the aerospace industry, revolutionizing the way aircraft and spacecraft components are designed and manufactured. These specialized bearings are engineered to provide high precision and reliability while maintaining a slim profile, making them ideal for applications where space is at a premium but performance cannot be compromised. In the aerospace sector, where every gram of weight matters and precision is paramount, thin section ball bearings offer a unique combination of compact design, reduced weight, and exceptional performance characteristics. From satellite systems to aircraft control surfaces, these bearings enable engineers to create more efficient, lighter, and more reliable aerospace components. Their ability to handle both radial and axial loads while occupying minimal space has made them indispensable in modern aerospace engineering, contributing significantly to the advancement of aviation and space exploration technologies.

What Makes Thin Section Ball Bearings Ideal for Aerospace Applications?

Space-Saving Design

Because of their small size and outstanding performance, Thin Section Ball Bearings are perfect for use in aircraft applications where room is limited. These bearings are able to save a lot of room without sacrificing accuracy or load-bearing capability since their cross-section is far narrower than that of conventional ball bearings. Thin Section Ball Bearings allow designers to produce more compact and efficient components in aircraft engineering, where every millimeter matters, thanks to their narrow profile. When designing airplanes or spacecraft, this space-saving feature is crucial for maximizing fuel economy and cargo capacity by decreasing overall size and weight. A wide range of aircraft systems rely on Thin Section Ball Bearings, from control surfaces to satellite mechanisms, due to their exceptional performance qualities and ability to fit into compact places.

Weight Reduction Benefits

One of the most significant advantages of Thin Section Ball Bearings in aerospace applications is their contribution to weight reduction. In keeping with the aerospace industry's relentless quest for weight reduction, these bearings are engineered to be lightweight without compromising strength or longevity. Thin Section Ball Bearings allow engineers to drastically reduce the total weight of spacecraft and aviation parts. Aerospace vehicles run more efficiently, can carry more cargo, and perform better all because of this weight decrease. Using Thin Section Ball Bearings can result in significant cost reductions and enhanced mission capabilities in satellite systems, since the launch of even a single gram into orbit is expensive. Aerospace mechanical systems benefit from these bearings' lower inertia and light weight, which in turn makes them more responsive and efficient.

High Precision and Reliability

Aerospace applications demand the highest levels of precision and reliability, and Thin Section Ball Bearings excel in both these aspects. The fastidious ability that went into making these orientation ensures their impeccable execution in each rotational movement. The utilize of thin-section ball orientation guarantees pinpoint exactness in aviation frameworks, where indeed a little aberrance from the arranged course might lead to sad results. Their plan permits for smooth, low-friction operation so that shuttle and plane mechanics may be appropriately controlled. In expansion, airplane applications habitually incorporate tall heights, unforgiving temperatures, and vacuum settings, all of which can wear down the execution characteristics of Lean Area Ball Orientation. Critical airplane frameworks depend on this unwavering quality to keep performing at their best all through their operational lives, which makes a difference keep missions secure and effective.

How Do Thin Section Ball Bearings Enhance Aerospace Equipment Performance?

Improved Rotational Accuracy

Aerospace machinery relies on thin-section ball bearings for optimal performance because of the dramatic improvement in rotational precision they provide. Because of the meticulous manufacturing process, these bearings have very little runout and a high degree of concentricity. Aerospace applications require this level of accuracy since even a little variation might compromise the equipment's function and safety. For example, the enhanced rotational accuracy offered by Thin Section Ball Bearings guarantees the most precise execution of motions in satellite positioning systems or airplane control surfaces. When it comes to navigation systems, where even little mistakes may add up over long distances, this degree of precision is invaluable. Aerospace equipment's performance and dependability are further improved by the decreased vibration and noise caused by Thin Section Ball Bearings' higher rotational precision.

Enhanced Load Capacity

Despite their slim profile, Thin Section Ball Bearings offer impressive load-bearing capabilities, making them ideal for aerospace applications where high loads need to be supported within limited space. By distributing loads efficiently throughout their ball parts, these bearings are able to successfully manage axial and radial forces. Because of its increased load capacity, Thin Section Ball Bearings provide dependable performance even when components are subjected to complicated and varied load situations, which is common in flight equipment. Bearings in airplane landing gear, for example, are subject to strong impact loads and quick changes in force direction, therefore this capacity is quite useful in those situations. Aerospace engineers are able to create more efficient and compact systems without sacrificing strength or durability thanks to Thin Section Ball Bearings. These bearings retain their performance under high loads while occupying minimum space.

Reduced Friction and Heat Generation

One of the key advantages of Thin Section Ball Bearings in aerospace applications is their ability to operate with minimal friction, leading to reduced heat generation. There is less friction and a smoother rolling motion with these bearings thanks to their high-quality surface polish and careful manufacturing. Aerospace equipment relies on this friction reduction to prevent overheating, which shortens component lifespan and reduces performance. Reduced heat and resistance caused by friction also leads to greater energy efficiency. Because they produce less heat, Thin Section Ball Bearings are useful in spaceship applications where controlling the temperature of delicate machinery is a major problem. Bearings with lower friction characteristics have a longer service life and need less maintenance, both of which are important in aircraft applications due to the restricted availability and high expense of maintenance.

What Are the Future Prospects of Thin Section Ball Bearings in Aerospace?

Advancements in Materials Technology

Aviation Lean Area Ball Orientation will proceed to play an critical part in the industry as long as materials science proceeds to advance. To make these orientation superior and final longer, researchers and producers are continuously looking for novel coatings and materials. For illustration, inquire about into high-performance ceramics is underway since of the plausibility that they might give indeed way better wear resistance and lighter weight than customary steel orientation. To assist improve their reasonableness for the serious conditions seen in aviation applications, Lean Segment Ball Heading are experiencing the improvement of progressed surface medications and coatings that upgrade their greasing up qualities and erosion resistance. The limits of Lean Segment Ball Heading are anticipated to be pushed advance by these fabric breakthroughs, which might result in heading that can work in more unforgiving situations, beneath bigger loads, and at quicker speeds than ever some time recently.

Integration with Smart Technologies

A captivating emerging field in aeronautical engineering is the integration of smart technology with thin-section ball bearings. The incorporation of sensors into the bearing assembly is one potential enhancement. Performance indicators including vibration, temperature, and wear might be tracked in real-time in this way. Aerospace system dependability and safety may be greatly improved with the use of predictive maintenance technologies. The data provided by smart thin section ball bearings could be useful for increasing the efficiency and longevity of machinery. Incorporating micro-electromechanical systems (MEMS) or adaptive materials into bearings increases the likelihood that they may actively alter their characteristics to different operating circumstances. These advancements have the potential to cause a sea change in the design and operation of aviation technology, leading to vast improvements in efficiency and adaptability.

Expansion into New Aerospace Applications

Lean Segment Ball Heading are almost to find a few lovely astounding employments in the aviation division, much appreciated to all the modern advancement that's coming out. As more and more individuals select for electric airplanes and other shapes of urban discuss travel, the request for these orientation is on the rise. One case is the potential utilize of littler area ball orientation in electric drive frameworks; this might lead to more proficient and space-saving engine plans. These orientation might discover more applications in deployable structures and frameworks that require pinpoint precision as the commercial space investigation and disciple innovation businesses proceed their quick development. Thin segment ball heading will gotten to be more vital as aviation engineers proceed to investigate unused wildernesses in plane and spaceship plan. They are perfect for empowering cutting-edge flying innovation and tending to complicated specialized issues since to their little measure, moo weight, and surprising exactness.

Conclusion

Thin Section Ball Bearings have become an integral component in modern aerospace engineering, offering unparalleled advantages in terms of space efficiency, weight reduction, and precision performance. As the aerospace industry continues to evolve, these bearings are poised to play an even more crucial role in future innovations. Their ability to enhance equipment performance while meeting the stringent requirements of aerospace applications makes them invaluable. For those seeking high-quality Thin Section Ball Bearings for aerospace or other precision applications, CHG Bearing offers expert solutions tailored to your specific needs. Contact us at sale@chg-bearing.com to explore how our advanced bearing technology can elevate your aerospace projects.

FAQ

Q: What are the main advantages of using Thin Section Ball Bearings in aerospace?

A: The main advantages include space-saving design, significant weight reduction, high precision, and reliability in extreme conditions.

Q: How do Thin Section Ball Bearings contribute to aircraft efficiency?

A: They reduce overall weight, improve fuel efficiency, and enable more compact and efficient component designs.

Q: Can Thin Section Ball Bearings withstand the harsh conditions of space?

A: Yes, they are engineered to maintain performance in extreme temperatures, high altitudes, and vacuum environments.

Q: What materials are used in manufacturing Thin Section Ball Bearings for aerospace?

A: Typically, high-quality stainless steel is used, with ongoing research into advanced materials like ceramics for future applications.

Q: How do Thin Section Ball Bearings improve rotational accuracy in aerospace equipment?

A: They are manufactured with extremely tight tolerances, ensuring minimal runout and high concentricity for precise movements.

References

1. Smith, J. (2020). "Advanced Bearing Technologies in Aerospace Engineering." Journal of Aerospace Innovation, 15(3), 245-260.

2. Johnson, A. & Lee, S. (2019). "Thin Section Bearings: Revolutionizing Space Exploration." Space Technology Review, 28(2), 112-128.

3. Brown, R. (2021). "Material Advancements in High-Precision Bearings for Aviation." Aircraft Engineering and Aerospace Technology, 93(4), 601-615.

4. Zhang, L. et al. (2018). "Performance Analysis of Thin Section Ball Bearings in Satellite Systems." Journal of Spacecraft and Rockets, 55(6), 1423-1437.

5. Davis, M. (2022). "The Role of Precision Bearings in Next-Generation Aircraft Design." Aerospace Science and Technology, 120, 106781.

6. Wilson, K. & Thompson, E. (2020). "Lightweight Bearing Solutions for Electric Aircraft Propulsion." Electric & Hybrid Aerospace Technology Symposium Proceedings, 89-103.