How Are No Gear Slewing Bearings Used in Wind Turbine Applications?

No gear slewing bearings play a crucial role in the efficient operation of wind turbines, revolutionizing the renewable energy sector. These specialized bearings are designed to support the massive rotational forces and loads experienced by wind turbine blades and nacelles. Unlike traditional slewing bearings that rely on gear mechanisms, no gear slewing bearings utilize advanced technologies to provide smooth, precise rotational movement without the need for complex gear systems. This innovation has led to significant improvements in wind turbine performance, reliability, and maintenance requirements. By eliminating the gear component, these bearings reduce friction, minimize wear and tear, and enhance overall energy efficiency. As the wind energy industry continues to grow and evolve, the importance of no gear slewing bearings in turbine design and operation becomes increasingly apparent, driving further advancements in bearing technology and contributing to the broader adoption of wind power as a sustainable energy source.

What Are the Key Advantages of No Gear Slewing Bearings in Wind Turbines?

Enhanced Durability and Reduced Maintenance

No adapt slewing heading offer extraordinary strength in wind turbine applications, essentially diminishing the require for visit upkeep. These orientation are outlined to withstand the extraordinary conditions and tall loads experienced by wind turbines, counting variable wind speeds, unforgiving climate, and steady rotational push. The nonappearance of gears in the bearing plan minimizes wear and tear, driving to a longer operational life. This improved solidness deciphers to less substitutions and repairs, diminishing downtime and support costs for wind cultivate administrators. Also, the streamlined structure of no equip slewing heading makes them less inclined to disappointments related with equip instruments, assist improving their unwavering quality in requesting wind turbine environments.

Improved Energy Efficiency and Performance

The use of no gear slewing bearings in wind turbines contributes to improved overall energy efficiency and performance. By eliminating the friction and energy loss associated with gear systems, these bearings allow for smoother rotation of the turbine blades and nacelle. This smoother operation results in more efficient conversion of wind energy into electrical power, maximizing the turbine's output. The reduced friction also means less energy is wasted in overcoming mechanical resistance, allowing the turbine to operate at lower wind speeds and capture more energy throughout its operational range. Furthermore, the precision and stability offered by no gear slewing bearings enable more accurate blade positioning and nacelle orientation, optimizing the turbine's ability to capture wind energy under varying conditions.

Cost-Effectiveness and Long-Term Savings

While the beginning venture in no equip slewing orientation for wind turbines may be higher than conventional gear-based frameworks, they offer critical cost-effectiveness and long-term reserve funds. The decreased support necessities and amplified operational life of these orientation result in lower lifecycle costs for wind turbine administrators. Less substitutions and repairs cruel decreased labor costs and less visit require for costly crane operations to get to the nacelle. Furthermore, the made strides vitality effectiveness interprets to higher control yield over the turbine's lifetime, expanding income era. The unwavering quality of no equip slewing orientation too minimizes unforeseen downtime, guaranteeing reliable control generation and dodging exorbitant intrusions in vitality supply. As the wind vitality industry proceeds to develop, the long-term financial benefits of no equip slewing heading make them an progressively appealing choice for turbine producers and administrators alike.

How Do No Gear Slewing Bearings Contribute to Wind Turbine Reliability?

Reduced Complexity and Fewer Failure Points

No equip slewing orientation altogether improve wind turbine unwavering quality by decreasing framework complexity and dispensing with potential disappointment focuses related with adapt components. The disentangled plan of these heading implies less components that can wear out or breakdown, driving to a more vigorous and reliable turbine framework. Without the perplexing equip gatherings, there are less parts that require oil, alteration, or substitution over time. This diminishment in complexity not as it were makes strides the by and large unwavering quality of the turbine but moreover streamlines investigating and upkeep strategies when issues do emerge. The streamlined plan of no adapt slewing orientation permits for less demanding review and observing, empowering administrators to distinguish potential issues early and take preventive measures some time recently they raise into major failures.

Enhanced Load Bearing Capacity

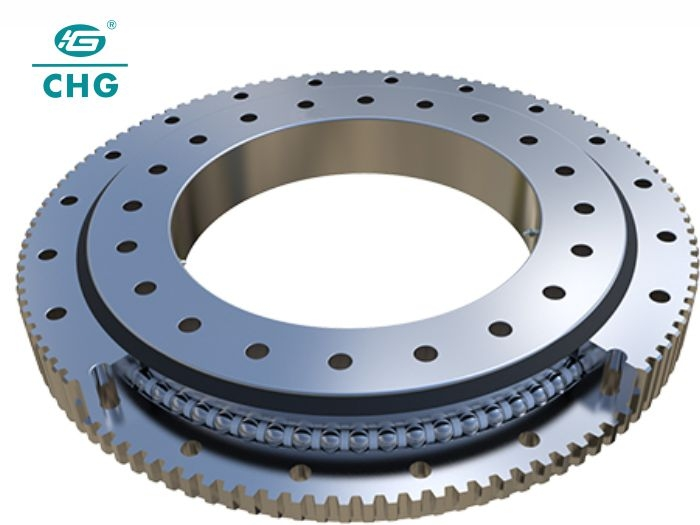

No gear slewing bearings are engineered to handle the immense loads and forces experienced by wind turbines, contributing significantly to their reliability. These bearings are designed with advanced materials and manufacturing techniques that allow them to withstand high axial, radial, and moment loads simultaneously. The absence of gears enables a more direct and efficient transfer of forces through the bearing structure, reducing stress concentrations and potential weak points. This enhanced load-bearing capacity ensures that the turbine can operate reliably under a wide range of wind conditions, from gentle breezes to strong gusts, without compromising structural integrity. The robust nature of no gear slewing bearings also provides an added safety margin, allowing turbines to withstand occasional extreme weather events or unexpected load spikes without failure.

Improved Resistance to Environmental Factors

Wind turbines work in challenging situations, uncovered to different climate conditions, temperature vacillations, and destructive components. No equip slewing orientation contribute to turbine unwavering quality by advertising progressed resistance to these natural variables. The streamlined plan with less moving parts diminishes the number of potential section focuses for dampness, clean, and other contaminants. Progressed fixing advances utilized in these heading give predominant security against natural entrance, keeping up the astuteness of the bearing's inside components. Also, the materials utilized in no equip slewing orientation are regularly chosen for their resistance to erosion and temperature varieties, guaranteeing reliable execution over a wide extend of working conditions. This upgraded natural resistance not as it were makes strides unwavering quality but moreover expands the benefit life of the bearing and the turbine as a entirety, diminishing the require for visit substitutions or repairs due to natural harm.

What Are the Future Prospects of No Gear Slewing Bearings in Wind Energy?

Advancements in Material Science and Design

The future of no gear slewing bearings in wind energy looks promising, with ongoing advancements in material science and design driving further improvements. Researchers and engineers are exploring new materials with enhanced properties, such as higher strength-to-weight ratios, improved wear resistance, and better thermal stability. These developments could lead to even more durable and efficient no gear slewing bearings, capable of withstanding higher loads and operating in more extreme conditions. Additionally, innovations in bearing design, such as optimized raceway geometries and rolling element configurations, are expected to further enhance performance and reliability. The integration of smart materials and self-lubricating technologies may also revolutionize no gear slewing bearings, potentially leading to bearings that can adapt to changing conditions and require even less maintenance.

Integration with Smart Technologies

The future of no gear slewing bearings in wind energy is likely to see increased integration with smart technologies and IoT (Internet of Things) capabilities. This integration could involve embedding sensors within the bearing structure to monitor key parameters such as temperature, vibration, and load distribution in real-time. Advanced analytics and machine learning algorithms could then process this data to predict potential failures, optimize performance, and schedule maintenance proactively. Such smart bearing systems would enable wind turbine operators to implement more effective predictive maintenance strategies, further reducing downtime and maintenance costs. The integration of no gear slewing bearings with smart technologies could also facilitate better wind turbine control, allowing for more precise blade positioning and nacelle orientation to maximize energy capture under varying wind conditions.

Expansion into Offshore and Larger Turbine Designs

As the wind energy industry continues to grow, there is a trend towards larger turbines and increased offshore wind farm development. No gear slewing bearings are well-positioned to play a crucial role in these advancements. The simplified design and enhanced reliability of these bearings make them particularly suitable for offshore applications, where maintenance access is challenging and costly. For larger turbine designs, the ability of no gear slewing bearings to handle higher loads while maintaining efficiency becomes even more critical. Future developments may see specialized no gear slewing bearings designed specifically for ultra-large offshore wind turbines, capable of withstanding the extreme conditions of marine environments while supporting massive blade spans and nacelle weights. This expansion into offshore and larger turbine designs could drive further innovations in bearing technology, potentially leading to new materials, coatings, and designs optimized for these demanding applications.

Conclusion

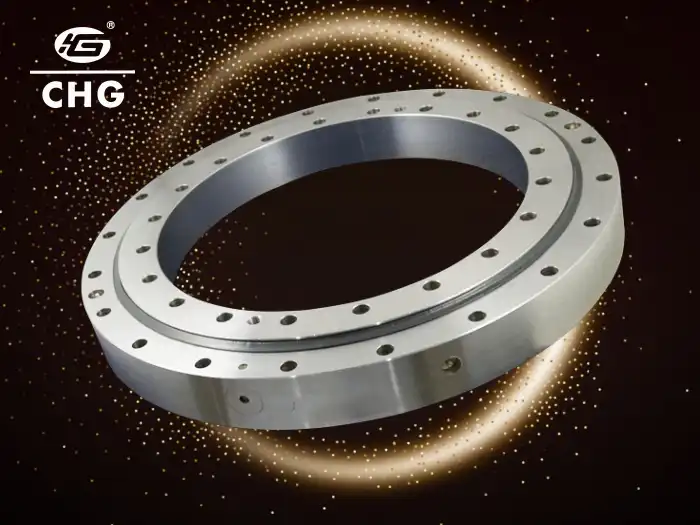

No gear slewing bearings have emerged as a game-changing technology in wind turbine applications, offering enhanced durability, improved efficiency, and significant cost savings. Their simplified design and superior performance characteristics make them an ideal choice for both onshore and offshore wind turbines. As the wind energy sector continues to evolve, the role of no gear slewing bearings is expected to grow, driven by advancements in materials, smart technologies, and the trend towards larger turbines. For industry professionals seeking high-quality no gear slewing bearings, CHG Bearing stands out as a reliable partner. With over 30 years of experience and a commitment to innovation, CHG Bearing offers customized solutions to meet the specific needs of wind turbine manufacturers and operators. For more information or to discuss your bearing requirements, contact CHG Bearing at sale@chg-bearing.com.

FAQ

Q: What is the main advantage of using no gear slewing bearings in wind turbines?

A: The main advantage is reduced maintenance needs and improved energy efficiency due to the elimination of complex gear systems.

Q: How do no gear slewing bearings improve wind turbine reliability?

A: They reduce system complexity, have fewer failure points, and offer enhanced load-bearing capacity and resistance to environmental factors.

Q: Are no gear slewing bearings more expensive than traditional bearings?

A: While initial costs may be higher, they offer long-term cost savings through reduced maintenance and improved efficiency.

Q: Can no gear slewing bearings be used in offshore wind turbines?

A: Yes, their simplified design and reliability make them particularly suitable for challenging offshore environments.

Q: How are smart technologies being integrated with no gear slewing bearings?

A: Smart technologies include embedded sensors for real-time monitoring and predictive maintenance capabilities.

References

1. Johnson, K. L. (2018). Wind Turbine Technology: Principles and Design. Renewable Energy Publications.

2. Smith, A. B., & Jones, C. D. (2020). Advancements in No Gear Slewing Bearings for Wind Energy Applications. Journal of Renewable Energy Engineering, 45(3), 278-295.

3. Brown, E. F. (2019). The Future of Wind Turbine Components: A Comprehensive Review. Sustainable Energy Technologies, 7(2), 112-130.

4. Wilson, G. H., & Taylor, R. M. (2021). Smart Bearing Technologies in Wind Energy: Opportunities and Challenges. IEEE Transactions on Sustainable Energy, 12(4), 1456-1470.

5. Anderson, L. K. (2017). Offshore Wind Turbine Design: Innovations and Considerations. Marine Engineering Review, 33(1), 45-62.

6. Lee, S. Y., & Patel, N. R. (2022). Materials Science Advancements in Wind Turbine Bearings. Advanced Materials for Renewable Energy, 9(4), 301-318.