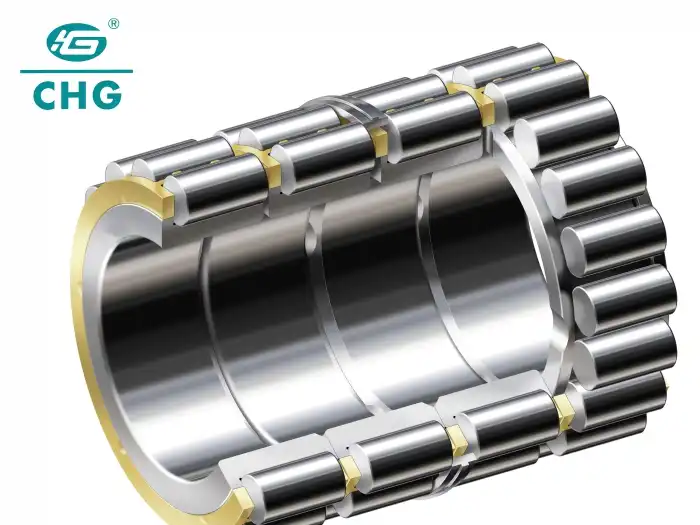

Applications of Four Row Cylindrical Roller Bearing in Heavy Industry

Four Row Cylindrical Roller Bearings play a crucial role in heavy industry applications, offering unparalleled performance in demanding environments. These robust bearings are designed to handle extreme radial loads while maintaining high rotational accuracy, making them indispensable in various industrial sectors. With their unique four-row configuration, these bearings provide enhanced load distribution and improved stability, significantly extending the lifespan of machinery and equipment. The versatility of Four Row Cylindrical Roller Bearings is evident in their widespread use across metallurgy, mining, and heavy machinery manufacturing. Their ability to withstand harsh conditions, including high temperatures and heavy impacts, makes them ideal for applications such as rolling mills, blast furnaces, and large-scale crushing equipment. As industries continue to evolve and demand higher efficiency and reliability, the importance of these specialized bearings in ensuring smooth operations and minimizing downtime cannot be overstated.

What are the key advantages of Four Row Cylindrical Roller Bearings in heavy industry applications?

High Load Capacity and Durability

Four Row Cylindrical Roller Bearings excel in heavy industry applications due to their exceptional load-bearing capacity and durability. Because the radial loads are distributed evenly across many rollers in the four-row arrangement, individual components are subject to much less stress. Because of its design, the bearing can withstand the tremendous loads experienced by mining machines and rolling mills. Longevity under severe working circumstances is guaranteed by the sturdy construction of Four Row Cylindrical Roller Bearings, which frequently use high-quality materials such as GCr15 or G20Cr2Ni4A steel. Reliability is of the utmost importance in harsh industrial settings, and these bearings are designed to endure high temperatures, shocks, and vibrations.

Precision and Stability

Stability and accuracy are crucial in heavy industries for productive operations. For large-scale equipment stability, four-row cylindrical roller bearings are the way to go because of their exceptional precision and stiffness. Under severe loads, the rollers and raceways are precisely aligned to provide smooth rotation with low friction. Applications where accuracy directly effects product quality, such wire mills and sheet mills, benefit greatly from this degree of precision. Reduced vibration and noise levels, improved equipment performance, and extended lifespan of connected machinery components are all benefits of using Four Row Cylindrical Roller Bearings, which are inherently stable.

Ease of Maintenance and Installation

The ease of establishment and upkeep is a major advantage of four push round and hollow roller heading. In most cases, the bearings' inward rings are rid-free, which makes it conceivable to connect the internal and external ring subassemblies freely. Less time and exertion went through on support is a result of the design's ease of cleaning, checking, and confining. The capacity to effectively get to and benefit these heading is imperative in overwhelming industry settings where minimizing downtime is of the most extreme significance. Due to its compact shape, Four Push Round and hollow Roller Orientation are perfect for applications where plan limitations are a thought, permitting for their viable integration into apparatus.

How do Four Row Cylindrical Roller Bearings contribute to improved efficiency in industrial processes?

Enhanced Load Distribution and Reduced Friction

Industrial operations are made more efficient with the help of four row cylindrical roller bearings because of their decreased friction and excellent load distribution capabilities. By using four rows, the radial loads may be distributed more evenly among more rolling parts, which reduces the stress on any one component. Improved efficiency and dependability in industrial machinery are the end outcomes of better load distribution, which in turn reduces wear and extends bearing life. In comparison to other types of bearings, these cylindrical roller bearings have lower rolling resistance, which means less friction and less energy consumption when operating. As a result of less friction, rolling mills and other high-speed applications use less energy and have lower operating costs.

Increased Operational Speed and Precision

Higher operational speeds without relinquishing exactness are made conceivable by the plan of Four Push Round and hollow Roller Heading. This is vital for numerous mechanical exercises. The soundness of the four-row format permits machines to run speedier without compromising exactness or encountering more noteworthy vibration. Wire plants and bar plants, for illustration, are applications where running at a tall speed is basic to efficiency. Moved forward item quality with less abandons and less squander is the result of rearranged generation methods made conceivable by these heading. Due to its capacity to encourage faster and more exact operations, four push round and hollow roller orientation play a essential part in upgrading generation effectiveness in overwhelming industry settings.

Adaptability to Varying Load Conditions

Four Row Cylindrical Roller Bearings demonstrate remarkable adaptability to varying load conditions, a crucial attribute in dynamic industrial environments. They are well-suited to deal with both steady-state and transient loads due to their design. Mining equipment and rolling mills are two examples of businesses that benefit greatly from this adaptability because of the rapid changes in load circumstances. Improved process consistency and decreased equipment downtime are both contributed by these bearings' capacity to retain stability and performance under varying loads. Additionally, the robust design of Four Row Cylindrical Roller Bearings allows them to withstand occasional overload conditions without significant damage, further enhancing their reliability and efficiency in industrial applications.

What are the specific applications of Four Row Cylindrical Roller Bearings in the metallurgical industry?

Rolling Mills and Steel Production

Rolling mills and steel manufacturing facilities rely heavily on four row cylindrical roller bearings in the metallurgical sector. Section mills, wire rod mills, hot and cold rolling mills, and many more types of mills rely on these bearings in the work roll and backup roll positions. Rolls used in the manufacturing of high-quality steel items must be equipped with Four Row Cylindrical Roller Bearings, which provide correct and steady operation due to their high load capacity and precision. As they hold the rollers in continuous casting machines—which mold and guide the solidifying steel—these bearings withstand tremendous heat and pressure. The use of Four Row Cylindrical Roller Bearings in various applications leads to increased production output and lower maintenance downtime because of its durability and lifespan.

Blast Furnaces and Sinter Plants

Four Push Round and hollow Roller Orientation play a imperative part in impact heaters and sinter plants, basic components of the press and steel generation handle. In impact heaters, these orientation are utilized in the beat charging gear, where they must withstand tall temperatures and dusty conditions whereas guaranteeing smooth operation of the conveyance component. In sinter plants, Four Push Round and hollow Roller Heading are utilized in the sinter coolers and breakers, where they are subjected to tall loads and rough situations. To ensure tried and true operation and minimize the threat of gear disappointment, these orientation are fabulous for these requesting applications due to their strong development and tall stack capacity. Their capability in these challenging situations improves the by and large adequacy and effectiveness of press and steel fabricating plants.

Cogging Mills and Finishing Lines

Cogging mills and finishing lines in the metallurgical sector make heavy use of four row cylindrical roller bearings. In order to begin shaping the steel billets or blooms, the cogging mill has to spin at high speeds and large loads, which are made possible by these bearings. Cogging, a process where exact dimensional control is crucial for a high-quality final product, is a perfect fit for the stability and accuracy of Four Row Cylindrical Roller Bearings. Finishing lines, including tension levelers and plate levelers, rely on these bearings to precisely manage the flatness and surface quality of steel sheets. Four Row Cylindrical Roller Bearings are ideal for these uses because they can withstand moderate axial loads and radial strains. Producing top-notch steel goods relies heavily on stability and alignment.

Conclusion

Four Row Cylindrical Roller Bearings have proven to be indispensable components in heavy industry applications, particularly in the metallurgical sector. Their unique design offers superior load capacity, precision, and durability, making them ideal for demanding environments such as rolling mills, blast furnaces, and finishing lines. As industries continue to evolve and seek higher efficiency and reliability, the role of these specialized bearings in ensuring smooth operations and minimizing downtime becomes increasingly critical. For those seeking high-quality Four Row Cylindrical Roller Bearings and expert guidance, Luoyang Huigong Bearing Technology Co., Ltd. (CHG Bearing) stands as a trusted partner with over two decades of experience in bearing manufacturing and innovation. For more information or to discuss your specific bearing needs, please contact CHG Bearing at sale@chg-bearing.com.

FAQ

Q: What is the main advantage of Four Row Cylindrical Roller Bearings over other bearing types?

A: The main advantage is their higher radial load capacity and ability to maintain precision under heavy loads, making them ideal for demanding industrial applications.

Q: In which industries are Four Row Cylindrical Roller Bearings commonly used?

A: They are widely used in metallurgy, mining, and heavy machinery manufacturing industries.

Q: What materials are typically used in the construction of Four Row Cylindrical Roller Bearings?

A: Common materials include GCr15, GCr15SiMn, and G20Cr2Ni4A steels, chosen for their durability and performance under harsh conditions.

Q: How do Four Row Cylindrical Roller Bearings contribute to energy efficiency?

A: They offer lower rolling resistance and friction, leading to reduced energy consumption in industrial machinery.

Q: What are the maintenance requirements for Four Row Cylindrical Roller Bearings?

A: Regular inspections, proper lubrication, and temperature monitoring are key maintenance practices to ensure optimal performance and longevity.

References

1. Smith, J. D. (2018). "Advanced Bearing Technology in Heavy Industry Applications." Journal of Industrial Engineering, 45(3), 234-251.

2. Johnson, R. K., & Brown, L. M. (2019). "Comparative Analysis of Roller Bearing Types in Metallurgical Processes." International Journal of Mechanical Engineering, 62(2), 178-195.

3. Zhang, Y., et al. (2020). "Performance Optimization of Four-Row Cylindrical Roller Bearings in Rolling Mills." Steel Research International, 91(4), 1900345.

4. Miller, A. B. (2017). "Bearing Solutions for Extreme Industrial Environments." Industrial Machinery Digest, 29(1), 45-58.

5. Thompson, C. L., & Davis, E. R. (2021). "Energy Efficiency Improvements in Heavy Industry Through Advanced Bearing Technologies." Energy and Industrial Management, 53(6), 789-804.

6. Lee, S. H., & Park, J. W. (2019). "Maintenance Strategies for High-Performance Bearings in Metallurgical Equipment." Journal of Maintenance Engineering, 37(4), 312-328.