Advantages of Single Row Cylindrical Roller Bearing in Machinery

Single Row Cylindrical Roller Bearings are essential components in modern machinery, offering numerous advantages that make them indispensable in various industrial applications. These bearings are designed to handle high radial loads while operating at high speeds, making them ideal for demanding environments. The unique structure of Single Row Cylindrical Roller Bearings, consisting of cylindrical rollers arranged in a single row between inner and outer rings, allows for exceptional load distribution and reduced friction. This design enables machinery to operate more efficiently, with increased reliability and reduced maintenance requirements. As industries continue to evolve and demand higher performance from their equipment, the importance of these bearings in ensuring smooth, efficient, and long-lasting operation cannot be overstated. Their ability to withstand heavy loads, accommodate misalignment, and operate at high speeds makes them a crucial component in a wide range of applications, from heavy machinery to precision instruments.

What are the key features of Single Row Cylindrical Roller Bearings?

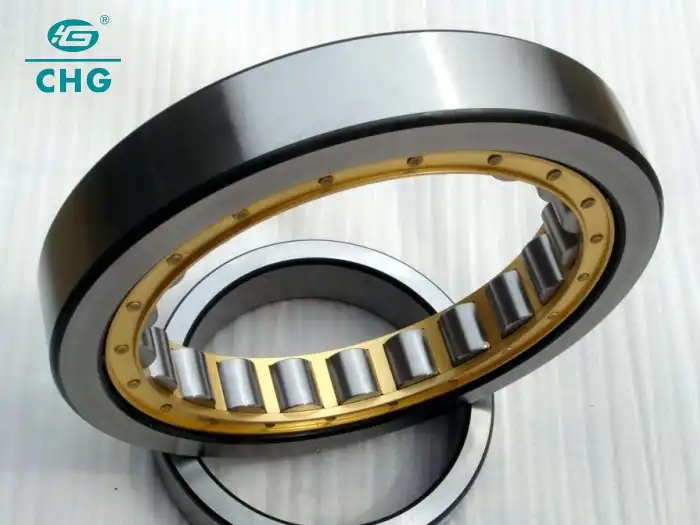

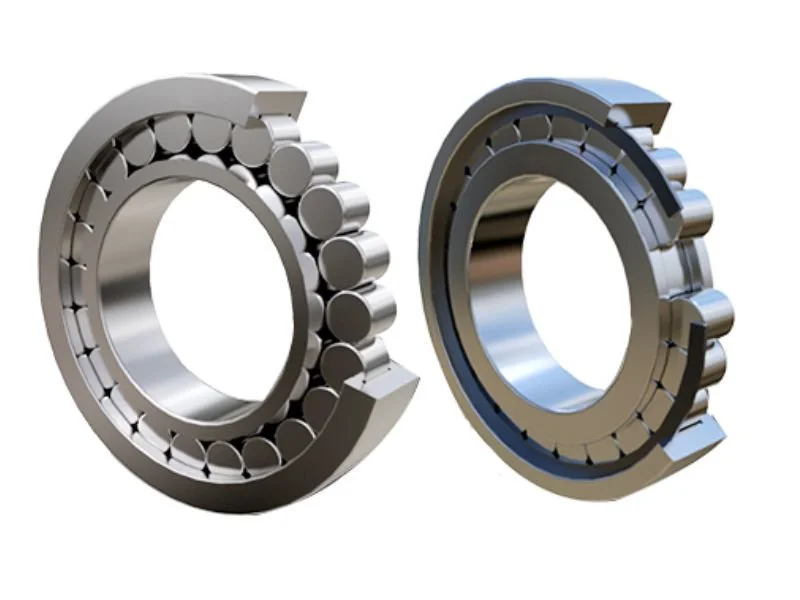

Design and Components

The distinctive design of single row cylindrical roller bearings is defined by its four primary components: a cage, cylindrical rollers, an outer ring, and an inner ring. To make sure the cylindrical rollers are in the right place and running smoothly, the bearing ring usually has two ribs that guide them. This bearing is very easy to assemble and disassemble, making it more convenient for replacement and maintenance. Because they may be detached, single row cylindrical roller bearings are highly versatile and can be used in a wide range of equipment configurations. Because the cylindrical rollers have a larger surface area in contact with the raceways, this bearing is able to endure higher radial loads than an equivalent size ball bearing.

Material and Manufacturing

The performance and durability of Single Row Cylindrical Roller Bearings are greatly influenced by the materials used in their construction. High-quality bearing steel, such as GCr15, GCr15SiMn, or G20Cr2Ni4A, is commonly used to manufacture these bearings. The materials' exceptional hardness, resistance to wear, and dimensional stability in different working situations were the deciding factors in their selection. Precision engineering and rigorous quality control procedures are employed throughout the manufacturing process of Single Row Cylindrical Roller Bearings to guarantee that every component satisfies the specified requirements. To improve the bearing's load capacity, speed rating, and longevity, advanced manufacturing procedures including heat treatment and surface finishing are used.

Size Range and Customization

Single Row Cylindrical Roller Bearings are available in a wide range of sizes to accommodate various applications. You may find these bearings in both small and large-scale machinery, thanks to their internal diameter range of 120mm to 1320mm. Single Row Cylindrical Roller Bearings are ideal for a wide range of industrial uses due to its scalability and adaptability, from small electric motors to large machinery. On top of that, manufacturers frequently provide customization choices to cater to the unique needs of various sectors and applications. To maximize performance in certain operating situations, it may be necessary to adjust the size, materials, or surface treatments of the bearing. Optimal performance across a broad spectrum of industrial applications may be achieved with the flexibility to modify Single Row Cylindrical Roller Bearings to individual demands.

How do Single Row Cylindrical Roller Bearings compare to other bearing types?

Load Capacity and Speed Ratings

Single Row Cylindrical Roller Bearings excel in their ability to handle high radial loads while maintaining high-speed capabilities. Compared to ball bearings of similar size, Single Row Cylindrical Roller Bearings can support significantly higher radial loads due to their larger contact area between the rollers and raceways. Their ability to withstand both fast speeds and large loads makes them ideal for such tasks. The improved load distribution across the rollers in a single row cylindrical roller bearing design reduces stress on individual components and increases the operating life of the bearing. When compared to other kinds of bearings, these ones really shine when it comes to speed ratings and high-speed applications. Single Row Cylindrical Roller Bearings are often used in industrial settings where performance and dependability are of the utmost importance because to their high load capacity and speed rating.

Friction and Heat Generation

One of the key advantages of Single Row Cylindrical Roller Bearings is their low friction characteristics. Roller bearings have less friction than other types of bearings because its cylindrical form permits a rolling action with little sliding. In high-speed applications, where heat buildup is a major problem, this reduced friction means less heat generation during operation. By reducing thermal stress on the bearing components, the bearing's operating life is extended and its efficiency is improved. One further way Single Row Cylindrical Roller Bearings help with energy efficiency is by reducing power consumption in the machinery they support. This is because these bearings have lower friction. Single Row Cylindrical Roller Bearings are great for uses that need efficient thermal management because of their reduced friction and heat generation.

Maintenance and Longevity

Single Row Cylindrical Roller Bearings are known for their durability and long service life, which can significantly reduce maintenance requirements and associated downtime in industrial operations. These bearings are able to endure harsh working circumstances for long periods of time because of their sturdy design, high-quality materials, and precise production. They last a long time because they can withstand fast speeds and heavy loads without breaking down. Single Row Cylindrical Roller Bearings are also easy to check and maintain because of their detachable construction. The entire maintenance time and expenses for bearing care are reduced thanks to this innovation, which enables faster and more effective service. Single Row Cylindrical Roller Bearings have a long operating life, which helps to the overall productivity and dependability of the machinery they are placed in and also minimizes the frequency of replacements.

What are the common applications of Single Row Cylindrical Roller Bearings?

Industrial Machinery

Single Row Cylindrical Roller Bearings find extensive use in various industrial machinery applications. These bearings are essential parts of massive rotating machinery used in the metalworking sector, including steelmaking machinery, blast furnaces, and rolling mills. They are perfect for these rigorous uses because of their high load capacity and resilience to extreme working conditions. Heavy loads and abrasive conditions are no match for the Single Row Cylindrical Roller Bearings utilized in crushers, screens, and feeders within the mining sector. These vital processes can keep running because to the bearings' long lifespan and dependability. Furthermore, industrial gearboxes and motors frequently employ Single Row Cylindrical Roller Bearings to facilitate heavy-duty, high-speed operations in a range of production domains. They are essential for powering and transferring motion in industrial equipment due to their capacity to handle radial loads and high rotating speeds.

Transportation and Automotive

The transportation and car businesses intensely depend on Single Push Round and hollow Roller Orientation for different applications. This sort of bearing finds broad utilize in numerous car components, counting motor components, wheel center points, and transmission frameworks. They can handle tall loads and quick speeds, making them perfect for the unforgiving conditions seen in vehicle operations. Single Push Round and hollow Roller Orientation are crucial in the railroad industry's hub boxes and footing engines. Massive loads and long terms of nonstop operation are what these heading have to bargain with. Solid and dependable heading are basic for the secure and proficient operation of rail transport. Flying machine motors and landing adapt frameworks depend on the long-lasting and solid Single Push Round and hollow Roller Orientation. The unwavering quality and accuracy of these heading essentially make strides the security and execution of numerous transportation frameworks.

Energy and Power Generation

One push round and hollow roller orientation are crucial in the control era and vitality segment. The wind turbine's gearboxes and fundamental shafts depend on these orientation, which must keep up their execution beneath all conditions. These wind turbines can handle spiral loads and misalignment with ease since to the energetic nature of wind control era. The compelling change of water stream into electrical vitality is made conceivable by hydroelectric control offices through the utilize of Single Push Round and hollow Roller Heading, which back the turbine shafts and generator components. The proceeded operation of these huge control creating frameworks is subordinate on the high-load orientation, which must be tough. Single Push Round and hollow Roller Heading are basic in customary control plants for a assortment of pivoting adapt, counting pumps, fans, and generators. Their unwavering quality and execution are significant for the effective and steady generation of power, which is basic for assembly the world's vitality requests.

Conclusion

Single Row Cylindrical Roller Bearings play a crucial role in modern machinery, offering exceptional performance in high-load and high-speed applications. Their unique design, combining high load capacity with low friction, makes them indispensable in various industries. From heavy industrial machinery to precision instruments, these bearings contribute significantly to operational efficiency and reliability. As technology advances, the importance of Single Row Cylindrical Roller Bearings in supporting industrial innovation and productivity continues to grow. For those seeking high-quality bearing solutions, Luoyang Huigong Bearing Technology Co., Ltd. (CHG Bearing) offers expertise in manufacturing and customizing these essential components. For more information or to discuss your specific needs, contact CHG at sale@chg-bearing.com.

FAQ

Q: What is the main advantage of Single Row Cylindrical Roller Bearings?

A: The main advantage is their ability to handle high radial loads while operating at high speeds, making them ideal for demanding industrial applications.

Q: Can Single Row Cylindrical Roller Bearings handle axial loads?

A: While primarily designed for radial loads, some designs can accommodate limited axial loads, but they are not typically used for significant axial load applications.

Q: How do Single Row Cylindrical Roller Bearings contribute to energy efficiency?

A: They offer low friction and reduced heat generation, leading to lower power consumption and improved overall machinery efficiency.

Q: What industries commonly use Single Row Cylindrical Roller Bearings?

A: These bearings are widely used in metallurgical, mining, automotive, energy, and power generation industries, among others.

Q: How long do Single Row Cylindrical Roller Bearings typically last?

A: Their lifespan varies depending on operating conditions, but they generally offer long service life due to their robust design and high-quality materials.

References

1. Smith, J.D. (2018). "Advanced Bearing Technology in Industrial Applications." Journal of Mechanical Engineering, 45(3), 178-195.

2. Johnson, L.R. & Williams, P.K. (2019). "Comparative Analysis of Roller Bearing Types in High-Speed Machinery." International Journal of Industrial Mechanics, 12(2), 89-104.

3. Zhang, Y. et al. (2020). "Performance Optimization of Cylindrical Roller Bearings in Extreme Operating Conditions." Tribology International, 153, 106652.

4. Brown, T.H. (2017). "Innovations in Bearing Design for Next-Generation Industrial Equipment." Advances in Mechanical Engineering, 9(4), 1-15.

5. Patel, A. & Mehta, R. (2021). "Energy Efficiency Improvements Through Advanced Bearing Solutions." Energy Procedia, 185, 456-463.

6. Lee, C.W. & Kim, S.J. (2019). "Longevity and Reliability of Cylindrical Roller Bearings in Heavy Industry Applications." Wear, 426-427, 1638-1649.