Full Complement Cylindrical Roller Bearing

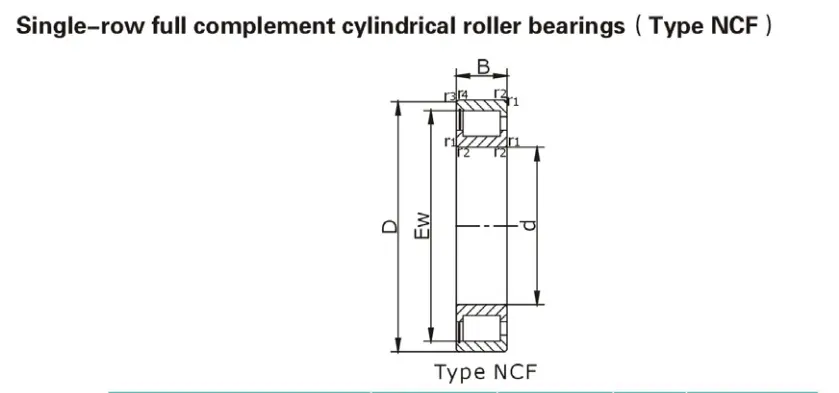

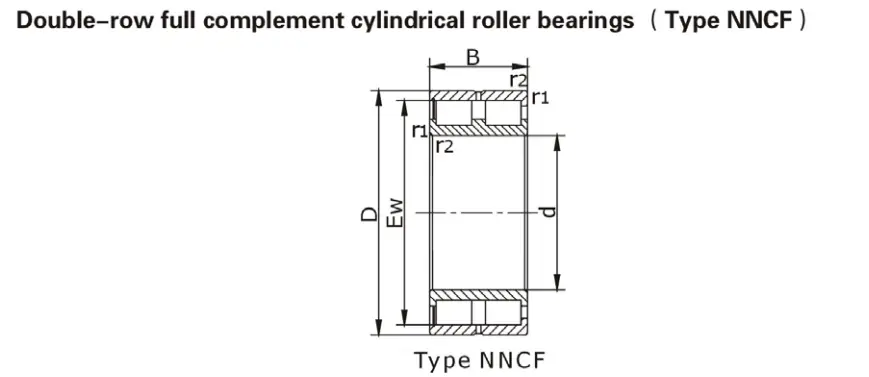

Its main optional structures include NCF (single-row) and NNCF (double-row).

NCF Design: single-row rollers, capable of bearing single direction axial load and acting as unidirectional locating bearing.

NNCF Design: double-row rollers, capable of bearing single direction axial load and acting as unidirectional locating bearing,applicable for low-speed and heavy load cases.

Open-type single-row and double-row full complement cylindrical roller bearings are mainly used to general mechanical equipment with low-speed and heavy-duty requirements. Close-type double-row full complement cylindrical roller bearings are mainly used for wire rope pulleys of cranes.

A Full Complement Cylindrical Roller Bearing is a specialized type of bearing designed to handle high radial loads with superior performance and durability. Unlike standard cylindrical roller bearings, a full complement bearing contains a complete set of rolling elements, which maximizes the bearing’s load-carrying capacity and rigidity. This design eliminates the need for a cage to separate the rollers, allowing for more rollers to be used, which translates into enhanced load distribution and a more compact bearing design.

Key Features:

- Increased Load Capacity: The full complement design allows for a higher number of rollers, increasing the bearing's load capacity and overall strength.

- Enhanced Rigidity: Without a cage, the rollers are positioned more densely, providing greater rigidity and reduced deflection.

- High Precision: Designed to meet the rigorous demands of high-precision applications, ensuring reliable and stable operation.

Production Process

Why Choose CHG Bearing?

At CHG Bearing, we take pride in being a leading manufacturer and supplier of Full Complement Cylindrical Roller Bearings. Here’s why you should consider us for your bearing needs:

1. Customization and Solutions for Various Working Conditions

We offer tailored solutions to meet the specific requirements of different operating environments. Whether you need bearings for high-temperature conditions, heavy loads, or specific dimensions, we provide customization to ensure optimal performance.

2. 30 Years of Industry Experience

With three decades of experience in the bearing industry, we have collaborated with numerous large companies, gaining invaluable insights and expertise. Our extensive knowledge ensures that we can meet and exceed your expectations.

3. Innovative and Quality Assurance

CHG Bearing holds more than 50 innovation licenses and has gotten ISO9001 quality administration framework and ISO14001 ecological administration framework certificates. Our obligation to quality and development ensures that our items satisfy the most noteworthy guidelines.

Feel free to reach out to us at sale@chg-bearing.com for any inquiries or custom solutions.

Technical Specifications

| Specification | Details |

|---|---|

| Type | Full Complement Cylindrical Roller Bearing |

| Material | GCr15/ GCr15SiMn/ G20Cr2Ni4A |

| Load Capacity | High radial load capacity |

| Operating Temperature | Wide range, up to 200°C |

| Precision | P0, P6, P5, P4 |

| Clearance | C0, C2, C3, C4 |

| Lubrication | Oil, grease, or customized options |

| Seal Type | Open, shielded, or sealed |

Full Complement Cylindrical Roller Bearing and Benefits

Benefits:

- Superior Load Handling: Capable of bearing heavier loads compared to standard roller bearings due to the increased number of rollers.

- Enhanced Durability: Designed to withstand harsh conditions and extended operational life, reducing maintenance and replacement costs.

- High Rigidity: Offers increased rigidity and precision, ideal for high-speed and high-load applications.

- Compact Design: Efficient use of space due to the lack of a cage, allowing for a more compact bearing setup.

Applications

Full Complement Cylindrical Roller Bearings are flexible and can be utilized in different requesting applications, including:

- Metallurgical Industry: Supporting large rotating equipment like blast furnaces, rolling mills, and steelmaking machines.

- Mining Machinery: Suitable for jaw crushers, impact crushers, vibrating screens, and feeders.

- Industrial Equipment: Ideal for high-load applications in machinery and equipment where durability and reliability are critical.

Installation Guide

Steps for Proper Installation:

- Preparation: Clean the bearing and the mounting surfaces thoroughly.

- Inspection: Check for any signs of damage or contamination before installation.

- Alignment: Ensure correct alignment of the bearing with the shaft and housing.

- Mounting: Carefully place the bearing onto the shaft, using proper tools and techniques to avoid damage.

- Lubrication: Apply the appropriate lubricant as specified for your bearing to ensure smooth operation.

Maintenance and Care

To maximize the lifespan of your Full Complement Cylindrical Roller Bearing, follow these maintenance practices:

- Regular Inspections: Periodically check for signs of wear, misalignment, or contamination.

- Proper Lubrication: Maintain appropriate lubrication levels to minimize friction and wear.

- Clean Environment: Keep the surrounding environment clean to avoid debris and contaminants.

- Monitoring: Use vibration and temperature monitoring tools to detect early signs of potential issues.

FAQ

Q: What is the advantage of a full complement design over a standard cylindrical roller bearing?

A: The full complement design offers a higher load capacity and greater rigidity due to the increased number of rollers and the absence of a cage.

Q: Can Full Complement Cylindrical Roller Bearings be customized?

A: Yes, we offer customization options to meet specific size, material, and lubrication requirements for various applications.

Q: What industries commonly use Full Complement Cylindrical Roller Bearings?

A: They are widely used in industries such as metallurgy, mining, and heavy machinery where high load capacities and durability are essential.

Customer Reviews

"CHG Bearing provided us with a full complement cylindrical roller bearing that exceeded our expectations. Their expertise and fast delivery were crucial to our production line's success." – John D., Production Manager

"Exceptional quality and excellent customer service. The customized bearing solution we received was perfect for our mining equipment." – Emily R., Technical Engineer

Contact Us

For more information or to request a quote, please contact us at sale@chg-bearing.com. Our team is ready to assist you with any questions or custom requirements you may have.

| Boundary dimensions | Basic load ratings | Designations | Mass | Limiting speeds | Installation dimersion | |||||||||

| mm | kN | kg | r/min | (mm) | ||||||||||

| d | D | B | r1、2min | r3、4min | Ew | Cr | Cor | Grease | Oil | da(min) | Da(max) | ra(max) | ||

| 150 | 210 | 36 | 2 | 1.1 | 195.5 | 289 | 505 | NCF2930V | 670 | 1400 | 159 | 201 | 2 | 3.7 |

| 225 | 56 | 2.1 | 1.1 | 211.7 | 460 | 710 | NCF3030V | 630 | 1300 | 161 | 214 | 2 | 7.1 | |

| 160 | 220 | 36 | 2 | 1.1 | 205.7 | 310 | 535 | NCF2932V | 630 | 1300 | 169 | 211 | 2 | 3.8 |

| 240 | 60 | 2.1 | 1.1 | 225.1 | 520 | 810 | NCF3032V | 600 | 1200 | 171 | 229 | 2 | 8.6 | |

| 170 | 215 | 22 | 1.5 | 1.1 | 203.5 | 149 | 272 | NCF1834V | 600 | 1200 | 182 | 204 | 1.5 | 1.8 |

| 230 | 36 | 2 | 1.1 | 216 | 320 | 570 | NCF2934V | 600 | 1200 | 179 | 221 | 2 | 4.1 | |

| 260 | 67 | 2.1 | 1.1 | 243.2 | 675 | 1070 | NCF3034V | 560 | 1100 | 181 | 249 | 2 | 11.9 | |

| 180 | 225 | 22 | 1.1 | 1 | 215.2 | 154 | 290 | NCF1836V | 600 | 1200 | 187.5 | 217.5 | 1 | 1.8 |

| 250 | 42 | 2 | 1.1 | 232 | 390 | 695 | NCF2936V | 560 | 1100 | 189 | 241 | 2 | 6 | |

| 280 | 74 | 2.1 | 2.1 | 260.5 | 785 | 1260 | NCF3036V | 560 | 1100 | 191 | 269 | 2 | 15.8 | |

| 190 | 240 | 24 | 1.5 | 1.1 | 229 | 178 | 335 | NCF1838V | 560 | 1100 | 198 | 232 | 1.5 | 2.4 |

| 260 | 42 | 2 | 1.1 | 244 | 435 | 785 | NCF2938V | 560 | 1100 | 199 | 251 | 2 | 6.5 | |

| 290 | 75 | 2.1 | 2.1 | 270 | 805 | 1320 | NCF3038V | 530 | 1000 | 201 | 279 | 2 | 16.7 | |

| 200 | 250 | 24 | 1.5 | 1.1 | 237.5 | 193 | 356 | NCF1840V | 560 | 1100 | 208 | 242 | 1.5 | 2.5 |

| 280 | 48 | 2.1 | 1.5 | 262 | 530 | 955 | NCF2940V | 530 | 1000 | 211 | 269 | 2 | 8.9 | |

| 310 | 82 | 2.1 | 2.1 | 288.2 | 910 | 1510 | NCF3040V | 500 | 950 | 211 | 299 | 2 | 21.4 | |

| 280 | 420 | 106 | 4 | 4 | 390.5 | 1740 | 3110 | NCF3056V | 49 | 360 | 670 | 302 | 395 | 3 |

| 300 | 380 | 38 | 2.1 | 1.5 | 363 | 445 | 870 | NCF1860V | 9.7 | 360 | 670 | 311 | 369 | 2 |

| 420 | 72 | 3 | 3 | 385 | 805 | 1730 | NCF2960V | 30.7 | 340 | 630 | 320 | 398 | 2.5 | |

| 460 | 118 | 4 | 4 | 432 | 1980 | 3500 | NCF3060V | 67.6 | 320 | 600 | 316 | 444 | 3 | |

| 320 | 400 | 38 | 2.1 | 1.5 | 383 | 460 | 925 | NCF1864V | 10.3 | 340 | 630 | 331 | 389 | 2 |

| 440 | 72 | 3 | 3 | 411 | 1150 | 2340 | NCF2964V | 33 | 320 | 600 | 333 | 427 | 2.5 | |

| 480 | 121 | 4 | 4 | 447.3 | 2170 | 3900 | NCF3064V | 73 | 300 | 560 | 336 | 464 | 3 | |

| 340 | 420 | 38 | 2.1 | 1.5 | 401 | 475 | 985 | NCF1868V | 10.7 | 320 | 600 | 359 | 402 | 2 |

| 460 | 72 | 3 | 3 | 431 | 1190 | 2470 | NCF2968V | 34.1 | 300 | 560 | 353 | 447 | 2.5 | |

| 520 | 133 | 5 | 5 | 486 | 2480 | 4350 | NCF3068V | 97 | 280 | 530 | 360 | 500 | 4 | |

| 360 | 440 | 38 | 2.1 | 1.5 | 423.2 | 562 | 1180 | NCF1872V | 11.5 | 300 | 560 | 371 | 429 | 2 |

| 480 | 72 | 3 | 3 | 451.5 | 1220 | 2610 | NCF2972V | 36 | 280 | 530 | 373 | 467 | 2.5 | |

| 540 | 134 | 5 | 5 | 503.2 | 2550 | 4600 | NCF3072V | 102 | 260 | 500 | 380 | 520 | 4 | |

| 380 | 480 | 46 | 2.1 | 1.5 | 458 | 575 | 1230 | NCF1876V | 18.6 | 280 | 530 | 391 | 469 | 2 |

| 520 | 82 | 4 | 4 | 486.7 | 1480 | 3210 | NCF2976V | 52 | 260 | 500 | 404 | 493 | 3 | |

| 560 | 135 | 5 | 5 | 520.5 | 2610 | 4800 | NCF3076V | 108 | 240 | 480 | 400 | 540 | 4 | |

| 400 | 500 | 46 | 2.1 | 1.5 | 475 | 590 | 1300 | NCF1880V | 19.5 | 260 | 500 | 411 | 489 | 2 |

| 540 | 82 | 4 | 4 | 511 | 1650 | 3550 | NCF2980V | 53.4 | 240 | 480 | 416 | 524 | 3 | |

| 600 | 148 | 5 | 5 | 559.1 | 2940 | 5450 | NCF3080V | 139 | 220 | 450 | 420 | 580 | 4 | |

| 420 | 520 | 46 | 2.1 | 1.5 | 499 | 600 | 1340 | NCF1884V | 20.5 | 240 | 480 | 431 | 509 | 2 |

| 420 | 560 | 82 | 4 | 4 | 524 | 1740 | 3590 | NCF2984V | 55.7 | 220 | 450 | 436 | 544 | 3 |

| 620 | 150 | 5 | 5 | 578.2 | 3000 | 5650 | NCF3084V | 147 | 200 | 430 | 440 | 600 | 4 | |

| 440 | 540 | 46 | 2.1 | 1.5 | 516 | 615 | 1410 | NCF1888V | 21.3 | 220 | 450 | 451 | 529 | 2 |

| 600 | 95 | 4 | 4 | 565.5 | 2100 | 4160 | NCF2988V | 78.2 | 200 | 430 | 456 | 584 | 3 | |

| 460 | 580 | 56 | 3 | 3 | 553 | 920 | 1950 | NCF1892V | 32.5 | 200 | 430 | 473 | 567 | 2.5 |

| 620 | 95 | 4 | 4 | 579 | 2130 | 4480 | NCF2992V | 81.2 | 190 | 400 | 476 | 604 | 3 | |

| 480 | 600 | 56 | 3 | 3 | 573.5 | 940 | 2040 | NCF1896V | 33.8 | 190 | 400 | 493 | 587 | 2.5 |

| 650 | 100 | 5 | 5 | 606 | 2380 | 5100 | NCF2996V | 95.1 | 180 | 380 | 500 | 630 | 4 | |

| 500 | 620 | 56 | 3 | 3 | 594 | 1030 | 2200 | NCF18/500V | 35 | 180 | 380 | 513 | 607 | 2.5 |

| 670 | 100 | 5 | 5 | 634.5 | 2420 | 5250 | NCF29/500V | 98.4 | 170 | 360 | 520 | 650 | 4 | |

| 530 | 650 | 56 | 3 | 3 | 624.5 | 990 | 2240 | NCF18/530V | 36.9 | 170 | 360 | 543 | 637 | 2.5 |

| 710 | 106 | 5 | 5 | 673 | 2700 | 6000 | NCF29/530V | 120 | 160 | 340 | 550 | 690 | 4 | |

| 560 | 680 | 56 | 3 | 3 | 655 | 1020 | 2360 | NCF18/560V | 39.3 | 160 | 340 | 573 | 667 | 2.5 |

| 750 | 112 | 5 | 5 | 709 | 3030 | 6700 | NCF29/560V | 140 | 150 | 320 | 580 | 730 | 4 | |

| 600 | 730 | 60 | 3 | 3 | 696 | 1140 | 2680 | NCF18/600V | 48.9 | 150 | 320 | 613 | 717 | 2.5 |

| 800 | 118 | 5 | 5 | 754 | 3360 | 7500 | NCF29/600V | 170 | 140 | 300 | 620 | 780 | 4 | |

| 630 | 780 | 69 | 4 | 4 | 739 | 1470 | 3400 | NCF18/630V | 68.8 | 140 | 300 | 646 | 764 | 3 |

| 850 | 128 | 6 | 6 | 807 | 3740 | 8650 | NCF29/630V | 205 | 130 | 280 | 656 | 824 | 5 | |

| 670 | 820 | 69 | 4 | 4 | 783 | 1520 | 3550 | NCF18/670V | 72.7 | 130 | 280 | 686 | 804 | 3 |

| 820 | 88 | 4 | 4 | 783 | 2040 | 5340 | NCF28/670V | 90.8 | 130 | 280 | 686 | 804 | 3 | |

| 710 | 870 | 74 | 4 | 4 | 831 | 1670 | 3900 | NCF18/710V | 79.7 | 120 | 260 | 726 | 854 | 3 |

| 950 | 140 | 6 | 6 | 896 | 3910 | 9150 | NCF29/710V | 275 | 110 | 240 | 736 | 924 | 5 | |

| 750 | 920 | 78 | 5 | 5 | 880 | 1890 | 4430 | NCF18/750V | 94.6 | 110 | 240 | 770 | 900 | 4 |

| 920 | 100 | 5 | 5 | 880 | 2630 | 6790 | NCF28/750V | 130 | 110 | 240 | 770 | 900 | 4 | |

| 800 | 980 | 82 | 5 | 5 | 936 | 2070 | 4930 | NCF18/800V | 113 | 100 | 220 | 820 | 960 | 4 |

| 1060 | 150 | 6 | 6 | 1002 | 4950 | 12200 | NCF29/800V | 360 | 95 | 200 | 836 | 1034 | 5 | |

| 850 | 1030 | 82 | 5 | 5 | 986 | 2050 | 5200 | NCF18/850V | 135 | 95 | 200 | 870 | 1010 | 4 |

| 1120 | 155 | 6 | 6 | 1061 | 5280 | 12900 | NCF29/850V | 405 | 90 | 190 | 886 | 1084 | 5 | |

| 900 | 1090 | 85 | 5 | 5 | 1044 | 2390 | 5900 | NCF18/900V | 139 | 90 | 190 | 920 | 1070 | 4 |

| 1180 | 165 | 6 | 6 | 1120 | 5940 | 14600 | NCF29/900V | 472 | 80 | 170 | 936 | 1154 | 5 | |

| 950 | 1150 | 90 | 5 | 5 | 1103 | 2420 | 6300 | NCF18/950V | 185 | 80 | 170 | 970 | 1130 | 4 |

| 1250 | 175 | 7.5 | 7.5 | 1179 | 6660 | 16300 | NCF29/950V | 565 | 75 | 160 | 983 | 1217 | 6 | |

| 1000 | 1220 | 100 | 6 | 6 | 1165 | 3110 | 7640 | NCF18/1000V | 209 | 75 | 160 | 1026 | 1194 | 5 |

| 1320 | 185 | 7.5 | 7.5 | 1252 | 7480 | 18600 | NCF29/1000V | 680 | 70 | 150 | 1033 | 1287 | 6 | |

| Boundary dimensions | Basic load ratings | Designations | Mass | Limiting speeds | Installation dimersion | ||||||||

| mm | kN | kg | r/min | (mm) | |||||||||

| d | D | B | r1、2min | Ew | Cr | Cor | Grease | Oil | da(min) | Da(max) | ra(max) | ||

| 150 | 210 | 60 | 2 | 192 | 390 | 865 | NNCF4930V | 6.6 | 670 | 1400 | 159 | 201 | 2 |

| 225 | 100 | 2.1 | 209 | 785 | 1420 | NNCF5030V | 13 | 630 | 1300 | 161 | 214 | 2 | |

| 160 | 220 | 60 | 2 | 203.9 | 410 | 930 | NNCF4932V | 7 | 630 | 1300 | 169 | 211 | 2 |

| 240 | 109 | 2.1 | 225 | 895 | 1620 | NNCF5032V | 15.8 | 600 | 1200 | 171 | 229 | 2 | |

| 170 | 230 | 60 | 2 | 212.2 | 415 | 975 | NNCF4934V | 7.3 | 600 | 1200 | 179 | 221 | 2 |

| 260 | 122 | 2.1 | 243 | 1160 | 2140 | NNCF5034V | 22.1 | 560 | 1100 | 181 | 249 | 2 | |

| 180 | 250 | 69 | 2 | 231.1 | 550 | 1230 | NNCF4936V | 10.7 | 560 | 1100 | 189 | 241 | 2 |

| 280 | 136 | 2.1 | 260.5 | 1340 | 2510 | NNCF5036V | 29.4 | 560 | 1100 | 191 | 269 | 2 | |

| 190 | 260 | 69 | 2 | 241.3 | 565 | 1290 | NNCF4938V | 11.1 | 560 | 1100 | 199 | 251 | 2 |

| 290 | 136 | 2.1 | 270 | 1380 | 2630 | NNCF5038V | 30.8 | 530 | 1100 | 201 | 279 | 2 | |

| 200 | 250 | 50 | 1.5 | 235.9 | 320 | 825 | NNCF4840V | 5.9 | 560 | 1100 | 208 | 242 | 1.5 |

| 280 | 80 | 2.1 | 260 | 665 | 1500 | NNCF4940V | 15.7 | 530 | 1000 | 211 | 269 | 2 | |

| 310 | 150 | 2.1 | 288 | 1560 | 3000 | NNCF5040V | 39.7 | 500 | 950 | 211 | 299 | 2 | |

| 220 | 270 | 50 | 1.5 | 256.9 | 340 | 905 | NNCF4844V | 6.4 | 530 | 1000 | 228 | 262 | 1.5 |

| 300 | 80 | 2.1 | 277.2 | 695 | 1620 | NNCF4944V | 17 | 500 | 950 | 231 | 289 | 2 | |

| 220 | 340 | 160 | 3 | 308.5 | 1570 | 3080 | NNCF5044V | 50.7 | 450 | 850 | 233 | 327 | 2.5 |

| 240 | 300 | 60 | 2 | 282.4 | 495 | 1340 | NNCF4848V | 10.3 | 480 | 900 | 249 | 291 | 2 |

| 320 | 80 | 2.1 | 300.1 | 725 | 1770 | NNCF4948V | 18.4 | 450 | 850 | 251 | 309 | 2 | |

| 360 | 160 | 3 | 335.6 | 1990 | 4000 | NNCF5048V | 54.3 | 430 | 800 | 253 | 347 | 2.5 | |

| 260 | 320 | 60 | 2 | 304.7 | 515 | 1450 | NNCF4852V | 11 | 430 | 800 | 269 | 311 | 2 |

| 360 | 100 | 2.1 | 331.5 | 1050 | 2530 | NNCF4952V | 32 | 400 | 750 | 271 | 349 | 2 | |

| 400 | 190 | 4 | 373.5 | 2690 | 5200 | NNCF5052V | 82.7 | 380 | 700 | 276 | 384 | 3 | |

| 280 | 350 | 69 | 2 | 332.9 | 685 | 1860 | NNCF4856V | 16 | 400 | 750 | 289 | 341 | 2 |

| 380 | 100 | 2.1 | 353.5 | 1090 | 2720 | NNCF4956V | 34 | 380 | 700 | 291 | 369 | 2 | |

| 420 | 190 | 4 | 389 | 2770 | 5450 | NNCF5056V | 87.7 | 360 | 670 | 296 | 404 | 3 | |

| 300 | 380 | 80 | 2.1 | 357.4 | 805 | 2160 | NNCF4860V | 23 | 380 | 700 | 311 | 369 | 2 |

| 420 | 118 | 3 | 390.2 | 1580 | 3800 | NNCF4960V | 52 | 340 | 630 | 313 | 407 | 2.5 | |

| 460 | 218 | 4 | 432 | 3400 | 7000 | NNCF5060V | 125 | 320 | 600 | 316 | 444 | 3 | |

| 320 | 400 | 80 | 2.1 | 380.3 | 835 | 2310 | NNCF4864V | 24.3 | 340 | 630 | 331 | 389 | 2 |

| 440 | 118 | 3 | 409 | 1620 | 4000 | NNCF4964V | 55 | 320 | 600 | 333 | 427 | 2.5 | |

| 320 | 480 | 218 | 4 | 447.5 | 3500 | 7350 | NNCF5064V | 131 | 300 | 560 | 336 | 464 | 3 |

| 340 | 420 | 80 | 2.1 | 397.4 | 855 | 2430 | NNCF4868V | 25.6 | 320 | 600 | 351 | 409 | 2 |

| 460 | 118 | 3 | 427.1 | 1690 | 4300 | NNCF4968V | 58 | 300 | 560 | 353 | 447 | 2.5 | |

| 520 | 243 | 5 | 486 | 4250 | 8750 | NNCF5068V | 177 | 280 | 530 | 360 | 500 | 4 | |

| 360 | 440 | 80 | 2.1 | 420.2 | 885 | 2580 | NNCF4872V | 27 | 300 | 560 | 371 | 429 | 2 |

| 480 | 118 | 3 | 446 | 1730 | 4500 | NNCF4972V | 61 | 300 | 560 | 373 | 467 | 2.5 | |

| 540 | 243 | 5 | 503.6 | 4190 | 8850 | NNCF5072V | 186 | 260 | 500 | 380 | 520 | 4 | |

| 380 | 480 | 100 | 2.1 | 456 | 1260 | 3600 | NNCF4876V | 45.5 | 280 | 530 | 391 | 469 | 2 |

| 520 | 140 | 4 | 481.5 | 2180 | 5650 | NNCF4976V | 90.5 | 260 | 500 | 396 | 504 | 3 | |

| 560 | 243 | 5 | 521.4 | 4280 | 9210 | NNCF5076V | 194 | 240 | 480 | 400 | 538 | 4 | |

| 400 | 500 | 100 | 2.1 | 470.3 | 1290 | 3750 | NNCF4880V | 47.5 | 260 | 500 | 411 | 489 | 2 |

| 540 | 140 | 4 | 502 | 2240 | 5900 | NNCF4980V | 94.5 | 240 | 480 | 416 | 524 | 3 | |

| 600 | 272 | 5 | 560 | 5050 | 10900 | NNCF5080V | 256 | 220 | 450 | 420 | 580 | 4 | |

| 420 | 520 | 100 | 2.1 | 492.6 | 1320 | 3950 | NNCF4884V | 49.5 | 240 | 480 | 431 | 509 | 2 |

| 560 | 140 | 4 | 522.5 | 2290 | 6200 | NNCF4984V | 98.5 | 220 | 450 | 436 | 544 | 3 | |

| 420 | 620 | 272 | 5 | 577.7 | 5150 | 11300 | NNCF5084V | 267 | 200 | 430 | 441 | 598 | 4 |

| 440 | 540 | 100 | 2.1 | 514.6 | 1350 | 4150 | NNCF4888V | 51.5 | 220 | 450 | 451 | 529 | 5 |

| 600 | 160 | 4 | 563.5 | 3000 | 7850 | NNCF4988V | 136 | 200 | 430 | 456 | 584 | 3 | |

| 460 | 580 | 118 | 3 | 543.3 | 1730 | 5150 | NNCF4892V | 77.5 | 200 | 430 | 473 | 567 | 2.5 |

| 620 | 160 | 4 | 577 | 3050 | 8050 | NNCF4992V | 142 | 190 | 400 | 476 | 604 | 3 | |

| 480 | 600 | 118 | 3 | 567.3 | 1760 | 5300 | NNCF4896V | 80.5 | 190 | 400 | 493 | 587 | 2.5 |

| 650 | 170 | 5 | 605.5 | 3350 | 8900 | NNCF4996V | 167 | 180 | 380 | 500 | 630 | 4 | |

| 500 | 620 | 118 | 3 | 583.5 | 1810 | 5600 | NNCF48/500V | 83.5 | 190 | 400 | 513 | 607 | 2.5 |

| 670 | 170 | 5 | 631.5 | 3400 | 9350 | NNCF49/500V | 173 | 170 | 360 | 520 | 650 | 4 | |